You may have noticed an unusual alert during your last visit to our site.Your activity seems to be perceived as that of an automated robot.Let’s explore the possible reasons for this confusion.

If you are using an anonymous proxy to connect, please disable it and try again. If the problem persists, feel free to contact our customer service by providing the following incident number: 6bd424e3-cy3y-4787-b1ec-1bc377a1622c. In the meantime, you can continue your browsing by clicking on the “I am human” box.

Table des matières

ToggleWhy is a pioneering heavy rare earth plant in France essential?

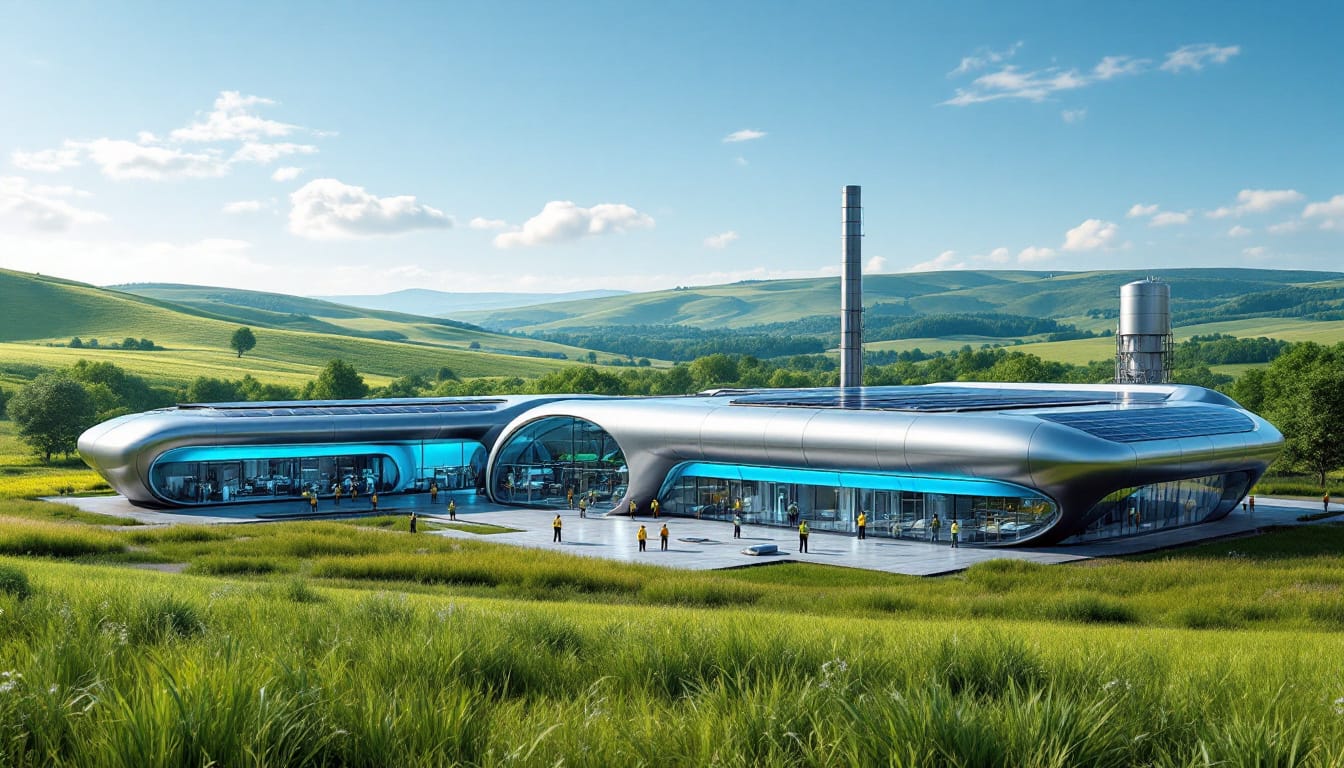

The emergence of a pioneering heavy rare earth plant in France marks a crucial step in the national industrial strategy. Rare earths are indispensable to many modern technologies, ranging from electric vehicles to advanced electronic equipment. By developing such an infrastructure, France aims to reduce its dependence on imports, mainly from China, and secure its supply of strategic materials. This initiative comes in a context where global demand for rare earths is constantly increasing, particularly with the energy transition and the growing digitalization of industries.

Moreover, this plant represents a major opportunity to boost the local economy and create highly skilled jobs. By investing in domestic production, France also positions itself as a key player in the European rare earth market, thereby enhancing its competitiveness and technological autonomy. This approach is accompanied by strategic partnerships with innovative companies, such as Solvay, which is actively engaged in developing sustainable solutions for the electric vehicle industry.

What are the components and technologies used in this plant?

The heavy rare earth plant in France uses cutting-edge technologies to extract and process these materials efficiently and environmentally responsibly. It integrates advanced cyber-physical systems, allowing for process automation and real-time optimization of production. These cloud technologies also facilitate data management and predictive maintenance of equipment, ensuring continuous and reliable production.

Furthermore, the plant adopts innovative recycling methods to minimize waste and maximize resource utilization. This circular approach aligns with the sustainability goals and carbon footprint reduction, which are essential in the current context of ecological transition. In addition, the integration of technologies such as solar paint developed by Mercedes-Benz demonstrates the plant’s commitment to innovation and adaptation to new industrial trends.

What are the expected economic and social impacts?

The creation of this plant is anticipated as an essential lever for the French economy. It will create hundreds of direct and indirect jobs, ranging from technical positions to administrative and commercial roles. This job creation dynamic will contribute to strengthening the local economic fabric and attracting specialized talent in the fields of advanced technologies and industrial production.

Additionally, the plant will promote the development of local sectors related to the extraction, processing, and research on rare earths. It will also stimulate innovation by encouraging partner companies to collaborate on research and development projects aimed at improving production processes and reducing costs. Thus, this initiative will have a positive impact on the overall competitiveness of the French industry, enhancing its ability to meet the technological and environmental challenges of the future.

What environmental and regulatory challenges need to be overcome?

The establishment of a heavy rare earth plant presents several challenges, particularly regarding environmental impact. The extraction and processing of rare earths are energy-intensive processes that generate potentially polluting waste. To address these issues, the plant adopts eco-friendly practices, such as recycling materials and using renewable energies to power operations.

Furthermore, it must comply with strict environmental and safety regulations. This includes regular audits, implementing protective measures for workers and local populations, as well as transparency in resource and waste management. Additionally, the plant must anticipate and adapt to legislative changes that may impact production processes and operational costs. This regulatory vigilance is essential to ensure the sustainability of the project and maintain the trust of stakeholders.

How does this initiative fit into the European dynamic?

The installation of this plant fits perfectly into the European strategy aimed at securing the supply of rare earths and promoting technological innovation. The European Union recognizes the strategic importance of these materials for industrial sovereignty and the energy transition. In France, this initiative reinforces European efforts to develop alternatives to imports and support local industries.

Moreover, this plant fosters cross-border cooperation in research and development, particularly with other European countries investing in rare earth technologies. It thus contributes to the creation of a European production and research network, facilitating knowledge sharing and the establishment of common standards. This European synergy is essential for remaining competitive against global industry giants, such as China, while ensuring a sustainable and responsible approach to the exploitation of critical resources.

Who are the key partners and investors in this project?

The success of this project relies on the collaboration of several key players, both at the national and international levels. Among the main partners are leading companies in the field of rare earths and advanced technologies, such as Solvay. The latter recently joined the rare earth sector in La Rochelle to support the development of electric vehicles, illustrating its commitment to this strategic sector.

Furthermore, financial institutions and private investors have expressed their confidence in the potential of the plant, providing the necessary capital for its establishment and operation. This synergy between the public and private sectors is essential to overcoming the financial and technical challenges associated with such a project. Additionally, partnerships with research centers and universities will contribute to ongoing innovation and improvement of production processes, thereby ensuring the competitiveness and sustainability of the plant in the long term.

What are the geopolitical impacts of this initiative?

The establishment of a heavy rare earth plant in France also has significant geopolitical repercussions. By diversifying its supply sources, France strengthens its resilience against trade tensions and dependencies on traditional producing countries, notably China. This increased autonomy helps reduce risks associated with fluctuations in global markets and protectionist policies.

Moreover, by becoming a key player in rare earth production within Europe, France plays a central role in the continent’s energy and industrial strategy. It contributes to the security of supply chains and the economic stability of the region. This strategic position can also strengthen France’s international alliances by actively participating in discussions and global initiatives on sustainable resource management and the transition to clean energies.

How does this plant contribute to innovation and research?

The heavy rare earth plant in France is designed as a center for innovation and advanced research. It integrates state-of-the-art laboratories where researchers work on improving the extraction and processing techniques for rare earths, aiming to increase efficiency and reduce environmental impacts. This approach fosters the emergence of new technologies and innovative solutions, thereby contributing to the competitiveness of the French industry in the global market.

Furthermore, the plant collaborates with research institutes and universities to develop advanced applications of rare earths in various sectors, such as electronics, renewable energy, and aerospace. These partnerships create a dynamic ecosystem where fundamental and applied research converge, stimulating innovation and promoting the rapid commercialization of scientific discoveries. This synergy between industrial production and research helps position France as a leader in the field of sustainable technologies and advanced materials.

What are the benefits for consumers and industry?

The opening of this plant brings a multitude of benefits for both consumers and industry. Consumers will benefit from greater availability and better quality products using rare earths, such as electric vehicles and electronic devices. Domestic and localized production reduces delivery times and associated costs while ensuring enhanced traceability and transparency of the materials used.

For the industry, this initiative represents an opportunity to strengthen local value chains and access high-quality materials at competitive costs. It also promotes innovation in developing new products and technologies by providing easier access to essential raw materials. Moreover, the geographical proximity of producers enables better collaboration and quick adaptation to market needs, thus stimulating growth and adaptability among French industrial companies.

How does this plant fit into the energy transition?

The heavy rare earth plant plays a key role in the energy transition by providing the materials necessary for the production of clean technologies. Rare earths are essential for the production of permanent magnets used in electric vehicle motors and wind turbines, as well as for advanced batteries that store renewable energy. By ensuring a stable supply of these materials, the plant directly contributes to reducing greenhouse gas emissions and promoting renewable energy.

Furthermore, the plant supports the development of CO2 capture and storage technologies, as well as other innovations aimed at improving the energy efficiency of industrial processes. By integrating these technological advances, the plant becomes not only a production center but also a driver of innovation for sustainable energy solutions. This synergy between production and energy transition is essential to meet the ambitious climate goals of France and the European Union.

What is the commissioning schedule and the next steps?

The commissioning of this heavy rare earth plant is scheduled for 2026, following several years of planning and construction. Currently, civil engineering works and equipment installation are underway, with strict adherence to quality and safety standards. The next steps include completing the technological infrastructure, training operational teams, and launching the first production phases.

Additionally, pilot tests will be carried out to validate production processes and optimize the plant’s performance. These tests will adjust operating parameters and ensure full-capacity production at the official opening. Once operational, the plant will enter a phase of continuous operation, with ambitious production goals and a particular focus on sustainability and energy efficiency. This schedule reflects the commitment to successfully completing this strategic project while ensuring optimal quality and performance.