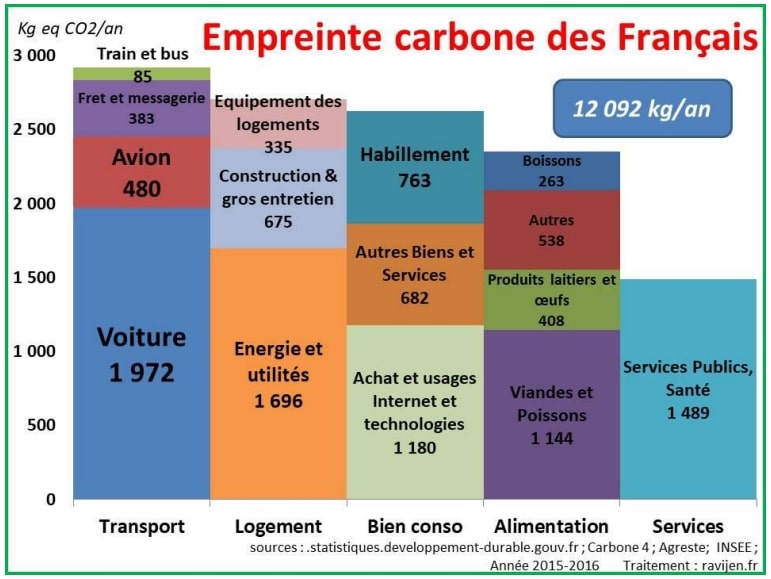

In an era where the climate crisis urges us to rethink our production models, a SME from Vaucluse, Le Coq Noir, stands out as a leader in sustainable innovation. Indeed, this company specializing in sauces and condiments is embarking on an ambitious project aimed at reducing its carbon footprint by 55%. How are they achieving this? Thanks to a concentrated solar power plant, a technology still underutilized in the French industrial sector, but promising. This initiative is part of a process of decarbonization of their production methods, as well as a desire to anticipate the impacts of fluctuations in energy prices, exacerbated by international crises. With the heat generated by this plant, the company aims to replace traditional energy systems, whose environmental impact is increasingly criticized. By partnering with innovative actors like the start-up Alto Solution, Le Coq Noir proves that even small and medium-sized enterprises can make a significant contribution to building a more sustainable and environmentally friendly future.

Table des matières

ToggleEnergy Revolution: A SME from Vaucluse Reduces its Carbon Footprint Thanks to a Concentrated Solar Power Plant

In a context where the energy transition has become an unavoidable necessity for businesses, Le Coq Noir, a food processing SME located in Vaucluse, has made a bold choice. By investing in a concentrated solar power plant, the company aims to reduce its carbon footprint by 50%. This initiative perfectly illustrates how a well-thought-out digital transformation and technical innovation can unite to create a sustainable industrial model.

Understanding Concentrated Solar Power Plants

A concentrated solar power plant (CSP) is an innovative technological device that uses mirrors or lenses to focus sunlight onto a receiver, thus producing high-temperature heat. This heat is then converted into electricity or used directly in industrial processes. Compared to conventional photovoltaic systems, CSP has the advantage of producing heat at temperatures exceeding 400 °C, making it ideal for sectors requiring heat for their processes.

The project led by Le Coq Noir is particularly significant, as it marks a first in the industrialization of this technology in France. In collaboration with the start-up Alto Solution, the company has bet on this technology to decarbonize its production process. According to recent studies, the use of concentrated solar power plants could help reduce global greenhouse gas emissions in France by 20% by 2030.

The Challenges and Benefits of Energy Transition for SMEs

Adopting an eco-responsible approach is not limited to satisfying an ecological conscience. The economic benefits of such decisions are numerous. By reducing its energy costs, Le Coq Noir will also be better positioned against increasingly demanding global competition regarding sustainability and corporate social responsibility.

The company’s general director, Thibaut de Leusse, emphasizes that there are few viable solutions to decarbonize heat, especially in the south of France where resources like geothermal energy are limited. Le Coq Noir thus illustrates how a SME can stand out by leveraging innovative solutions. Moreover, this initiative is supported by regional grants that help offset the high engineering costs associated with this type of transformation.

A significant outcome of this initiative is the ripple effect it could create. The agri-food sector, like the rest of the industry, is often criticized for its ecological footprint. If companies like Le Coq Noir can succeed in their energy transition, it may encourage others to follow suit, thus amplifying positive changes on a regional and national scale.

Practical Recommendations and Strategies to Adopt

For SMEs wishing to follow suit, some recommendations can be applied. First of all, it is crucial to conduct a comprehensive energy audit to identify consumption reduction opportunities. These diagnostics allow for aligning ecological goals while remaining economically viable.

Next, it is advisable to inform oneself about the various available technologies and assess which aligns best with the specific needs of the company. Partnerships with technology start-ups focused on renewable energy, like Alto Solution, can also facilitate the implementation of new systems.

Finally, raising awareness and training staff on environmental issues is paramount. Promoting a corporate culture focused on sustainability can yield beneficial effects both internally and externally, enhancing brand image and increasing customer loyalty.

By integrating these strategies, SMEs can not only comply with increasingly strict regulatory requirements regarding the environment but also take advantage of market opportunities that arise in this new green era. At a time when many players, such as Lactalis, are considering similar solutions, Le Coq Noir demonstrates that energy innovation is not reserved solely for large companies but is perfectly accessible to the local industrial fabric.

Frequently Asked Questions (FAQ)

What technology does the SME use to reduce its carbon footprint? The SME from Vaucluse uses a concentrated solar power plant to reduce its carbon footprint by 50%.

Why is the concentrated solar power plant effective? This technology is capable of providing sustainable heat at high temperatures, which is essential for industrial processes.

What impact does the war in Ukraine have on this project? The surge in gas prices amid the conflict has made the solar plant project viable, making the energy transition more urgent.

What are the dimensions of the constructed plant? The exact dimensions have not been specified, but it is a facility specifically calibrated for the SME’s factory.

How does the SME finance this project? The SME has received regional grants to absorb the significant engineering costs associated with the installation of the plant.

What is the goal in terms of emission reduction? The goal is to reduce its carbon balance by 50%, thereby improving the sustainability of its operations.