The pharmaceutical industry is rapidly evolving due to the integration of Industry 4.0 technologies. ACG, a major player in this field, offers innovative solutions to optimize production processes. By adopting a holistic approach, the transition to Pharma 4.0 improves the quality, efficiency, and compliance of products throughout the manufacturing cycle. The best practices and advanced equipment provided by ACG are key elements for successfully achieving this essential digital transformation.

The transition to Industry 4.0 in the pharmaceutical sector represents a significant challenge but also a major opportunity. ACG, a leading player in this field, offers innovative solutions to optimize production processes. This article explores ACG’s best practices for a successful implementation of Industry 4.0, focusing on aspects of digital transformation, automation, and the use of advanced information technologies.

Table des matières

ToggleDigital Transformation in the Pharmaceutical Sector

Digital transformation is at the heart of Industry 4.0 and plays a crucial role in the pharmaceutical sector. ACG recommends a holistic approach that encompasses all aspects of the company, from data management to production. Technologies such as cloud computing, Industrial Internet of Things (IIoT), and artificial intelligence are integrated to enhance the quality and compliance of pharmaceutical products.

Process Automation

To improve the performance and efficiency of production lines, ACG emphasizes automation. By using the Manufacturing Execution System (MES), factories can monitor and optimize their processes in real-time. The collected data allows for calculating the Overall Equipment Effectiveness (OEE), a key indicator for identifying bottlenecks and improving productivity.

Data Integrity and Security

Data integrity is crucial for ensuring regulatory compliance in the pharmaceutical sector. ACG implements advanced data management systems that ensure traceability and security of information. Implementing solutions like Blockchain helps secure sensitive data and guarantee its integrity throughout the product lifecycle.

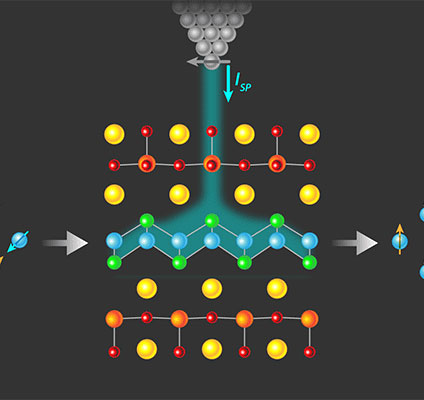

Process Optimization with IIoT

The Industrial Internet of Things (IIoT) plays a key role in process optimization. By connecting equipment and machines, ACG enables continuous data collection and analysis. This not only allows monitoring of production line performance but also predicts maintenance needs, thereby reducing downtime and increasing operational reliability.

Challenges and Best Practices

Implementing Industry 4.0 in the pharmaceutical sector comes with its share of challenges. ACG advises clearly defining priorities and adhering to best practices. Careful planning, ongoing training of personnel, and collaboration with experts are all key elements for successfully achieving this transition. It is essential to note that adherence to strict standards and regulations is crucial to ensure the safety and quality of products.

Example of Successful Implementation

ACG recently helped a pharmaceutical plant modernize its operations by integrating the principles of Industry 4.0. Through the use of MES and optimization of OEE data, the plant significantly improved its performance while ensuring compliance and traceability of its products. This example demonstrates the tangible benefits of automation and digital transformation for pharmaceutical sector companies.

- Advanced Equipment: Solutions designed to optimize production processes

- Automation: Improving access to medications through automation

- Pharma 4.0: Digital transformation of production

- OEE Data: Utilizing MES to monitor and optimize performance

- IIoT: Revolutionizing the pharmaceutical industry with the Industrial Internet of Things

- Data Integrity: Importance in the transition to Pharma 4.0

- Good Manufacturing Practices: Effective implementation of GMPs

- Compliance: Improving quality and compliance through Pharma 4.0

https://twitter.com/saintgobain/status/1791415310051950657