The era of Industry 4.0 opens fascinating horizons for economic sectors, particularly for the manufacturing field. In this context, Cisco, a global leader in digital technologies, has taken the initiative to unite with the Ministry of Industry and Advanced Technologies of the Emirates. Together, they aim to transform the industrial landscape of the Emirates by promoting the adoption of innovative technologies that define this new era.

This strategic partnership aims to enhance the competitiveness of local businesses by integrating advanced solutions such as IoT, data analytics, and cybersecurity. The current challenges, whether economic or technological, require a proactive and collaborative approach. By investing in the digital transformation of the manufacturing sector, Cisco and the ministry aim not only to optimize production processes but also to create a resilient and sustainable industrial ecosystem.

This alliance illustrates how the convergence of technological skills and government initiatives can catalyze the transition to a smart industry, where efficiency and innovation coexist to meet the needs of an ever-evolving market.

Table des matières

ToggleCisco and the Ministry of Industry: An Alliance for Industry 4.0 in the Emirates

In a world where technological progress redefines the boundaries of innovation, Cisco partners with the Ministry of Industry and Advanced Technologies of the United Arab Emirates to transform the landscape of the manufacturing sector through Industry 4.0. This collaboration aims to propel Emirati companies towards a future where connectivity and digital intelligence take precedence over traditional production methods.

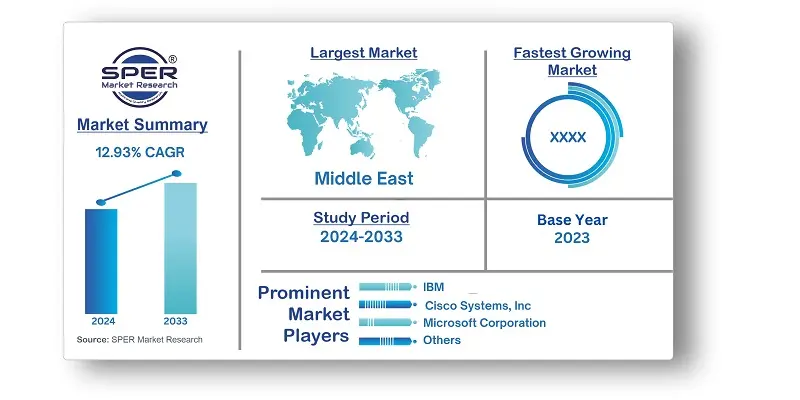

The adoption of Industry 4.0 is not just a trend but a necessity for countries seeking to increase their competitiveness in the global market. According to recent studies, Industry 4.0 could generate up to 14 trillion dollars by 2030 globally. This strategic alliance between Cisco and the UAE government is therefore a key element in catalyzing this potential.

A Strategic Adoption of Industry 4.0

The digital transformation in the manufacturing sector faces numerous obstacles, including resistance to change and a lack of appropriate skills. Cisco, leveraging its expertise in connectivity and data security, offers an integrated approach to encourage the adoption of Industry 4.0 technologies.

One of the major challenges lies in training professionals. Cisco has already initiated several skills development programs aimed at raising awareness and training employees in the use of advanced technologies such as artificial intelligence, the Internet of Things (IoT), and cybersecurity. A study conducted by Stanford University revealed that 87% of opinion leaders believe that the key to the success of Industry 4.0 lies in continuous training and adaptability of human resources.

In parallel, the objectives of this collaboration include the creation of an innovation ecosystem that brings together startups, established companies, and academic institutions. Events such as hackathons and co-creation workshops will incubate innovative projects that organizations eager to make the leap into digital transformation can rely on.

Towards a Sovereign Digital Economy

Establishing a robust and secure infrastructure for Industry 4.0 is essential. Cisco has already proven its effectiveness in this area through concrete projects. For example, the implementation of advanced communication networks for smart factories has demonstrated a 30% reduction in production lead times and a substantial increase in product quality.

The promising results of these initiatives allow us to envision a transformation that is not only technological but also economic. According to a report by McKinsey, companies that integrate Industry 4.0 see an average increase of 20% in their productivity. However, this yield should not come at the expense of sustainability. Promoting eco-responsible practices is also at the heart of this initiative, fostering not only operational efficiency but also the social responsibility of businesses.

To succeed in this transformation, manufacturing sector companies must adopt a clear strategy: integrate smart technologies, emphasize real-time data analysis, and enhance the self-learning capabilities of their systems. These elements are absolutely essential for optimizing their processes while reducing costs.

It thus becomes crucial for industrial stakeholders to equip themselves to acquire and maintain these new skills in the face of increasingly fierce competition on a global scale. Cisco’s support is based on tailored solutions that can accompany each step of the digitalization process.

Frequently Asked Questions About the Adoption of Industry 4.0 by Cisco and the MoIAT

Q: What is the main objective of the agreement between Cisco and the Ministry of Industry and Advanced Technologies? The main objective is to promote the adoption of Industry 4.0 in the manufacturing sector of the Emirates, in order to improve the competitiveness and efficiency of businesses.

Q: What are the main initiatives planned as part of this collaboration? The initiatives will include training programs, workshops on advanced technologies, and demonstrations of solutions to help businesses embrace digitalization.

Q: How is Industry 4.0 beneficial for the manufacturing sector? Industry 4.0 facilitates connectivity between machines and systems, allowing for better resource management, reduced production costs, and optimized processes.

Q: How does Cisco plan to support companies in this transition? Cisco plans to invest in cloud technologies and cyber-physical systems that enhance the digital transformation of businesses, while offering expertise and technical support.

Q: Which specific sectors will be impacted by this initiative? Although the focus is on the manufacturing sector, other sectors, including those related to logistics and smart production, may also benefit from this initiative.

Q: What role does training play in this partnership? Training is a key element, as it enables employees to acquire new skills and understand the technologies necessary to integrate Industry 4.0 into their operations.