The Digital Manufacturing represents the application of digital technologies to industrial production, aiming to optimize processes, machines, and productivity. This article explores the concept of digital manufacturing, its advantages for the industry of tomorrow, the technologies involved, and strategies for its implementation.

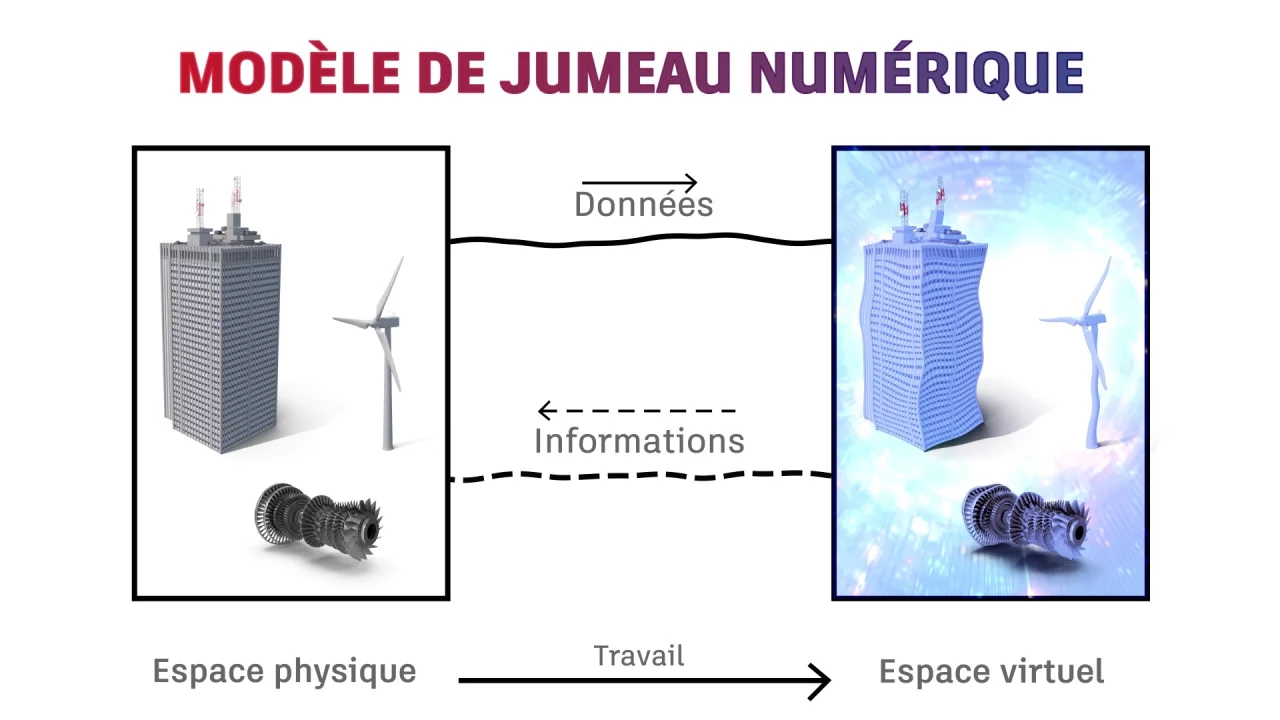

Digital Manufacturing refers to an integrated approach that uses advanced computer systems to enhance industrial processes. This digital transformation creates a symbiotic relationship between the physical and digital worlds through technologies such as 3D printing, computer-aided design (CAD), and computer numerical control (CNC).

Table des matières

ToggleStrategies for Implementing Digital Manufacturing

Establishing a Digital Factory is a crucial step toward fully leveraging digital innovations. A Digital Factory integrates cutting-edge software and technologies to support and enhance manufacturing processes. To effectively implement such a strategy, it is essential to assess the specific needs of the business and plan a detailed roadmap.

Assessment of Necessary Technologies

Before transitioning to digital manufacturing, businesses must identify the relevant technologies that will best meet their objectives. This may include adopting production management systems, cloud platforms for data storage and analysis, and simulation tools for testing and optimizing models before manufacturing.

Training and Skills Development

To successfully manage this transition, it is also crucial to train teams in the new technologies and processes. Employees must become familiar with digital systems and be capable of using them to maximize productivity. Investing in skills development ensures a smooth and efficient adoption of Digital Manufacturing.