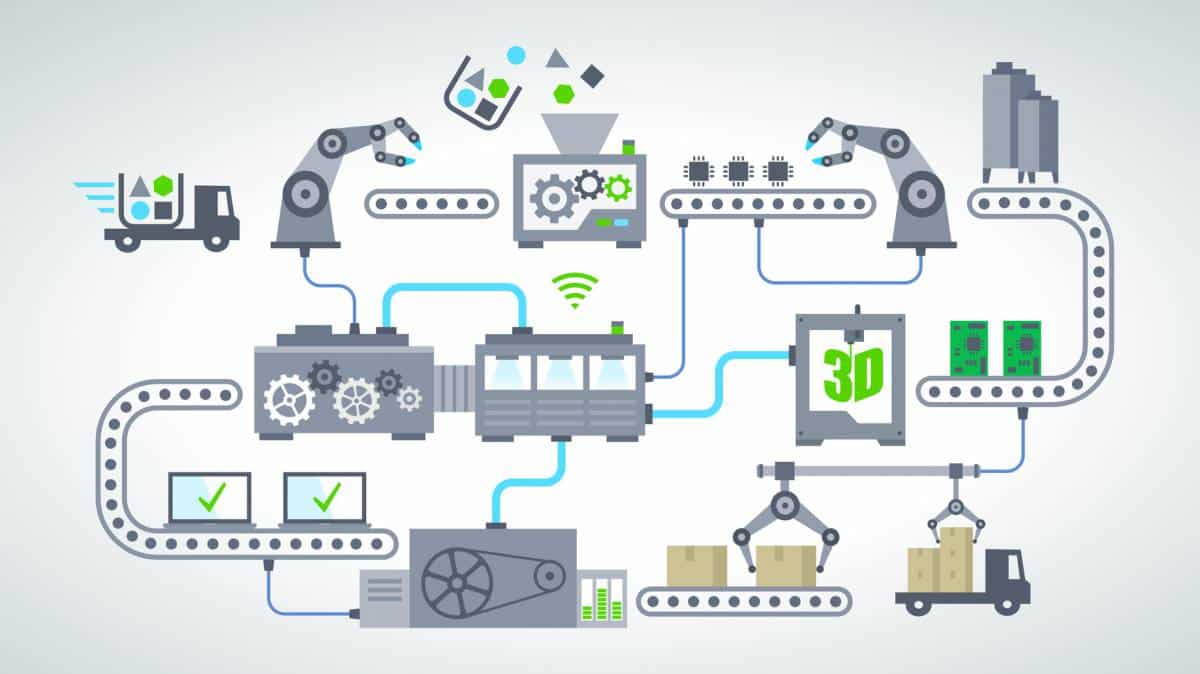

Dive into the heart of innovation with a new era of Industry 4.0, where the integration of edge AI pushes the known boundaries of smart manufacturing. This technological advancement transforms the interaction between machines and data, optimizing every step of the supply chain. Manufacturers can now operate with unmatched agility and precision, leveraging real-time data processing capabilities directly at the source, and pushing the limits of industrial productivity.

The new stage of Industry 4.0 is unfolding through the use of edge artificial intelligence (AI). This technological advancement allows for unprecedented optimization of the supply chain and manufacturing processes, by integrating technologies such as Internet of Things (IoT) and cloud computing. The fusion of these elements stimulates the agility, creativity, and efficiency of businesses while ensuring better connectivity and automation of systems.

Table des matières

Togglediscover the impact of edge AI on industry 4.0

The industry 4.0 revolution is redefining the industrial landscape with the continuous improvement of digital technologies. The introduction of edge AI means that processes, from the production chain to marketing strategies, are evolving to be more efficient and precise. This technology enables systems to interact in real-time, enhancing both monitoring and operational planning. This evolution is essential to cope with the increasing amount of data to be processed and analyzed, a trend that continues to grow in the global manufacturing sector.

Many companies are adopting edge AI to optimize their operations. By integrating this technology, they can anticipate failures, reduce machine downtime, and ensure maximum resource utilization. Moreover, this decentralized operating model transforms data into a strategic asset, allowing companies to respond better and faster to market needs. As industrialization intensifies, innovation becomes not only a competitive advantage but a necessity to adapt to new demands.

transformation of traditional manufacturing concepts

Edge AI goes well beyond basic functions, rethinking how information is collected and used. This ability to provide real-time solutions changes the game for industries that historically faced delays due to centralized collection and transmission. By facilitating a seamless integration of data, Industry 4.0 opens up new possibilities for design and manufacturing. Production becomes more agile, errors decrease, and an optimized production cycle emerges, illustrating the versatility of this revolutionary technology.

partnerships and collaborations for accelerated growth

In this transformation context, partnerships between technology companies serve as a pillar for rapid expansion. Collaborations allow for the combination of diverse expertise and effectively addressing the challenges of modernization. For example, the partnership between IBM and Amazon Web Services (AWS) demonstrates how technology leaders are leveraging these innovations to offer hybrid cloud solutions. These initiatives not only facilitate technological integration but also create a foundation for future sustainable development. These alliances reflect a commitment to leveraging the best available technologies to lead the future of industry.