additive manufacturing, often referred to as 3D printing, emerges as a cutting-edge technology at the heart of the industry of the future. It redefines the way physical objects are designed and produced by adding material progressively, layer by layer. From the outset, it utilizes computer-aided design (CAD) and 3D scanning, highlighting a method opposed to traditional machining, which subtracts material. By adopting various materials such as metal and polymer, this innovative technique revolutionizes various industrial sectors by enabling more flexible and customized production. The integration of machine learning propels this technology into digital transformation, offering promising applications for Industry 4.0.

Additive manufacturing, often referred to by the more popular term 3D printing, represents a major innovation in modern manufacturing processes. Unlike traditional machining, which is based on material removal, additive manufacturing operates by successively adding layers of material to create three-dimensional physical objects from digital models. This process utilizes various technologies and materials, allowing for great flexibility in design and production.

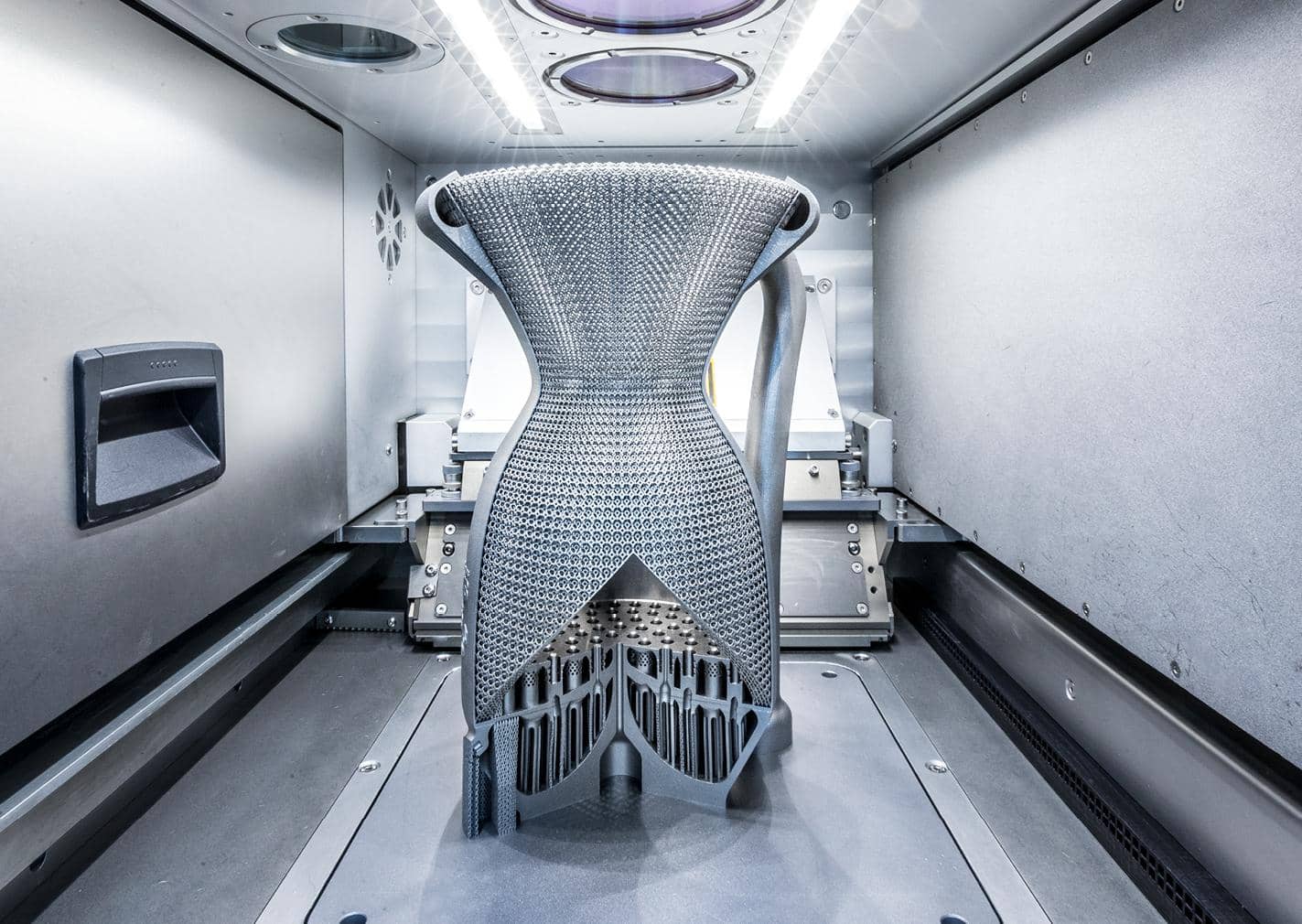

Among the main technologies used in additive manufacturing are stereolithography, which uses a laser to solidify layers of liquid resin; fused deposition modeling, where a plastic filament is extruded through a heated nozzle; and selective laser sintering, which involves melting and solidifying powder using a laser.

The materials used in additive manufacturing are varied. We can cite polymers, widely used in the field for their ease of use and relatively low cost. Metallic materials, although more complex to handle, are increasingly popular for applications in automotive, aerospace, or even healthcare. These technologies offer significant advantages in terms of customization and production times, especially for on-demand manufacturing.

The growing interest in additive manufacturing, especially in the context of Industry 4.0, promises to revolutionize traditional production methods. By integrating advanced solutions such as machine learning, 3D printing has established itself as a true vector of innovation. This propels initiatives towards an accelerated digital transformation in several sectors.

The applications of additive manufacturing are numerous. In the medical field, it is used to create customized prosthetics and anatomical models, while in the fashion industry, it enables the production of bespoke accessories. The manufacturing industry also benefits from innovations to optimize production, reduce lead times, and innovate products at lower cost.

Finally, the future of additive manufacturing relies partly on its ability to adapt to evolving industrial and technological needs, with companies like Safran working to integrate these innovations (as shown by Céline Carbiener at Safran). With the rise of factories of the future and the emergence of new economic models such as the circular economy, additive manufacturing is expected to continue its growth momentum.

Table des matières

ToggleFAQ about Additive Manufacturing or 3D Printing

Q: What is additive manufacturing?

A: Additive manufacturing is a process of creating three-dimensional objects by adding material layer by layer, using a digital file. This process is distinct from traditional machining, which involves removing material to form the desired part.

A: Yes, additive manufacturing and 3D printing are synonymous terms using various processes to construct 3D objects.

A: This technology enables rapid and flexible production, reduces material waste, and offers the ability to create complex geometries that would be impossible to achieve with traditional methods.

A: Additive manufacturing uses a variety of materials, including metals, polymers, ceramics, and certain composite materials, depending on the type of part and its purpose.

A: This technology is employed in many sectors such as aerospace, automotive, healthcare, and tooling production, due to its ability to rapidly create prototypes and customized products.

“`