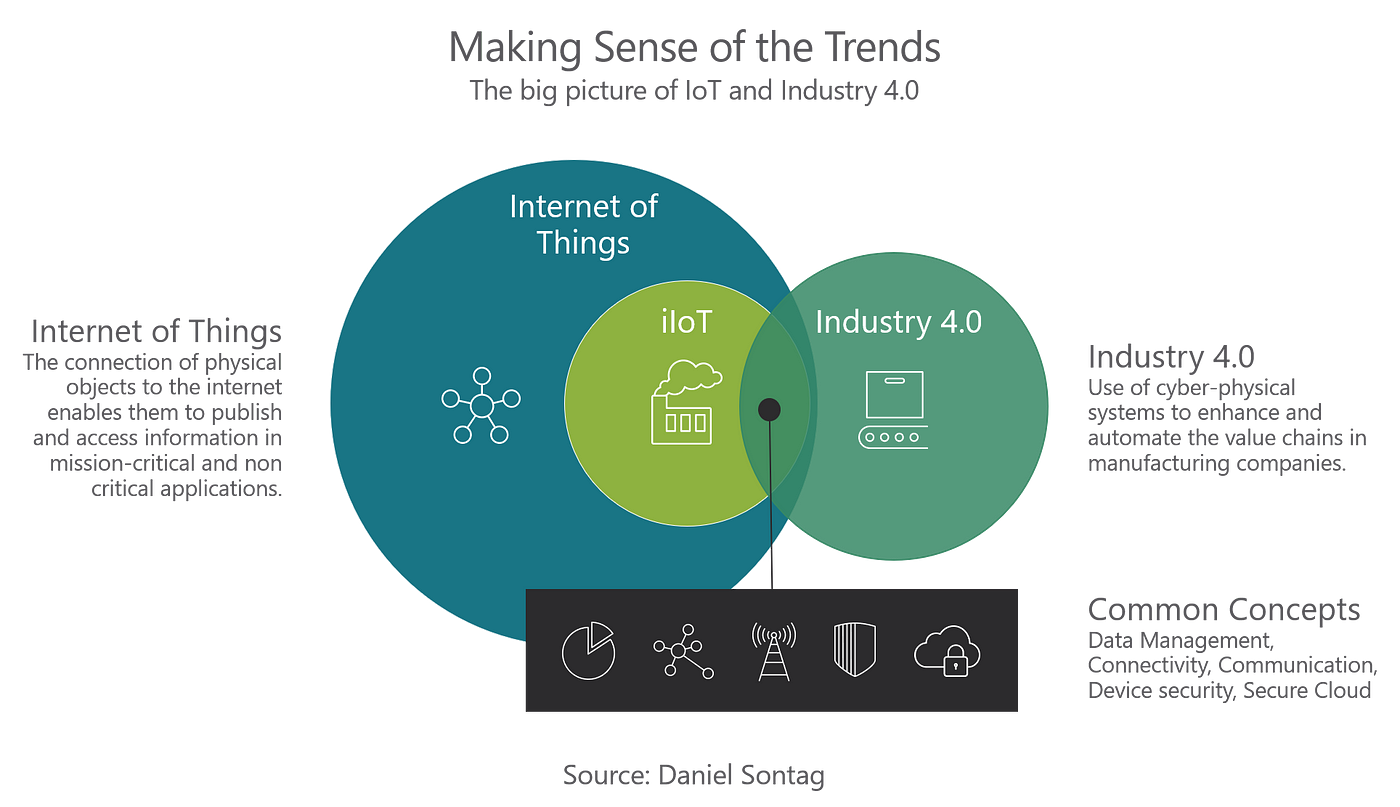

The era of Industry 4.0 is taking shape spectacularly with the integration of *5G*, exponentially increasing the potential of the Internet of Things (*IoT*). Thanks to higher data speeds, ultra-low latency, and massive connectivity, 5G is radically transforming the way smart factories, modernized warehouses, and flexible manufacturing facilities operate and interact with their environment. These places are the theaters of industrial renaissance where IoT, propelled by 5G, revolutionizes processes, optimizes infrastructures, and creates new opportunities for innovation-hungry businesses.

5G accelerates the transformation of Industry 4.0 through its exceptional capabilities, unlocking the potential of IoT in five key ways. First, it offers much faster data speeds and high bandwidth, allowing for rapid transmission of industrial data. Second, its extremely low latency facilitates instant communication between machines. Third, it ensures increased reliability and availability, even in remote industrial environments. Fourth, it enhances the capabilities of edge computing, enabling real-time data processing. Finally, it supports the massive connectivity of devices by connecting up to a million IoT devices simultaneously, which is essential for the technical complexity of Industry 4.0.

To fully leverage the opportunities offered by 5G in Industry 4.0, smart factories, predictive maintenance initiatives, and flexible manufacturing methods are three ideal environments where this transformation can materialize.

Table des matières

ToggleFive ways in which 5G unleashes the potential of IoT in Industry 4.0

In the current industrial era, 5G is much more than just a technological advancement. It represents a true revolution for Industry 4.0. By providing massive and reliable connectivity, it propels the Internet of Things (IoT) into new horizons. The ultrafast data speeds of 5G, coupled with increased bandwidth, allow machines, sensors, and robots to communicate without significant latency. This facilitates resource optimization and significantly increases operational efficiency.

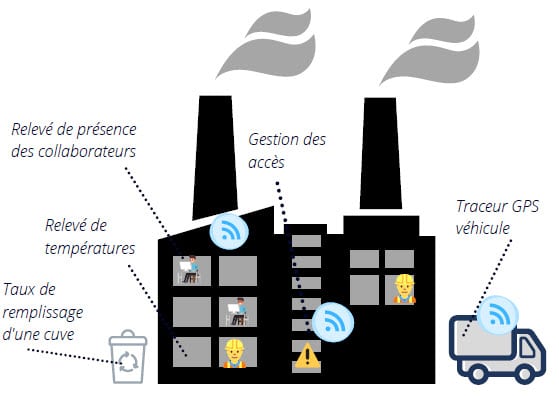

Integration of 5G and IoT for smart factories

With 5G, the most advanced designs become a reality. Smart factories can now use sensor networks to optimize their operations. Reduced latency ensures real-time operation, improving processes where every millisecond counts. By integrating intelligent systems, companies can anticipate and resolve equipment failures before they occur, thereby extending the lifespan of machines and reducing maintenance costs. Read more about 5G and its potential in this dedicated article.

Three exemplary places to discover the impact of 5G on Industry 4.0

For those curious to explore how 5G and IoT are transforming industrial landscapes, visiting exemplary sites is enriching. In Yvelines, France, for example, GE Healthcare has revolutionized the manufacturing of medical scanners by integrating 5G technologies. Additionally, the Botetourt Center in Greenfield offers free training on Industry 4.0, making it an ideal opportunity to discover innovations in real time. Finally, the industrial site in Indiana, undergoing digital transformation, demonstrates how the integration of 5G transforms not only efficiency but also the safety of industrial processes. These places embody the future of our digital age and serve as models to follow.

À combien de G résisteriez-vous ? 🫨

— ESA France (@ESA_fr) April 30, 2024

✈️ Un pilote d'avion de chasse jusqu'à 10G pendant une seconde ou deux

🏁 Un pilote de Formule 1 environ 5G en virage

🚀 Un astronaute autour de 3G au décollage

Notre mission #CometInterceptor est testée à un niveau d'accélération supérieur… pic.twitter.com/ttJ2hD361F