“`html

Welcome to our place. We are delighted by your interest. However, a regulatory constraint prevents us from welcoming you at this time.

Indeed, if you are accessing from a country in the European Economic Area, including the European Union, the provisions of the General Data Protection Regulation (GDPR) are strictly enforced. This regulation aims to ensure the confidentiality and security of your personal data. Unfortunately, this means that access to our site is currently restricted. For any questions or requests for assistance, please feel free to contact us at editorial@sme.org or by phone at 313-425-3000.

“`

“`html

Table des matières

ToggleWhy is Industry 4.0 crucial for manufacturers

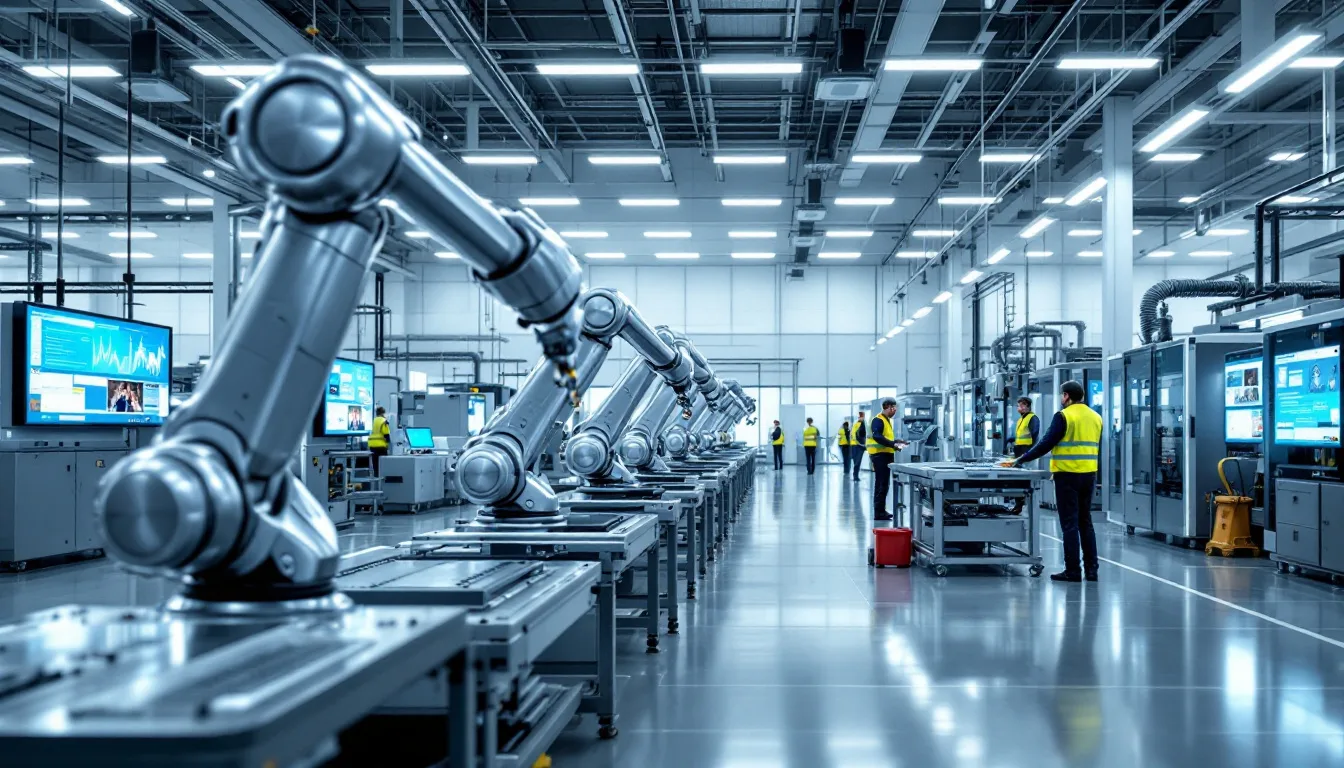

Industry 4.0 represents the fourth industrial revolution, marking a profound transformation in the way manufacturers operate. By integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and collaborative robotics, companies can optimize their processes, improve efficiency, and enhance their competitiveness in the global market. This transition to smart production allows manufacturers to respond more quickly to changing consumer demands while reducing costs and increasing product quality.

The adoption of Industry 4.0 also facilitates better management of supply chains by offering increased visibility and the ability to predict future needs through real-time data analysis. This proactive approach minimizes disruptions and ensures operational continuity, which is essential in a volatile economic environment. Furthermore, the integration of sustainable solutions within Industry 4.0 contributes to more environmentally friendly production, aligned with the growing expectations of consumers and regulators.

However, implementing these technologies requires significant investments and organizational adaptation. Manufacturers must rethink their business models and train their staff in the new skills required. Despite these challenges, the long-term benefits of Industry 4.0, such as agility, resilience, and continuous innovation, make it an essential endeavor for companies wishing to position themselves favorably in the industrial future.

What are the main challenges faced by manufacturers in adopting Industry 4.0

The adoption of Industry 4.0 is not without obstacles for manufacturers. One of the main challenges lies in the initial costs of technological investments. The acquisition and integration of advanced systems, such as machine vision solutions or data analysis platforms, require substantial financial resources. Furthermore, the maintenance and continuous updating of these technologies add an extra financial burden.

Another major challenge is the lack of specialized skills. The transition to smart production requires a qualified workforce capable of managing and leveraging new technologies. Manufacturers must invest in training their personnel or recruit new talent, which can represent a long and costly process. Moreover, resistance to change within organizations can hinder the adoption of innovations, making effective change management and transparent communication about the expected benefits essential.

Finally, issues of data security and regulatory compliance are significant obstacles. With the increasing volume of data generated and shared within industrial systems, protection against cyberattacks becomes crucial. Manufacturers must comply with strict regulations, including the General Data Protection Regulation (GDPR), to ensure the confidentiality and integrity of sensitive information. For instance, if a company attempts to access certain systems from the European Economic Area (EEA), restrictions may apply, requiring specific compliance measures.

To overcome these challenges, it is essential that manufacturers adopt a pragmatic approach, identifying the technologies most relevant to their operations and planning for gradual integration. Initiatives such as the launch of the Industry 4.0 Academy demonstrate how collaboration between educational and industrial institutions can facilitate the training of necessary skills and promote successful adoption of advanced technologies.

What technological innovations are driving Industry 4.0

Industry 4.0 relies on a set of technological innovations that radically transform manufacturing processes. Among these, the Internet of Things (IoT) plays a central role by connecting machines, sensors, and information systems, enabling seamless communication and real-time data collection. This interconnectivity fosters better coordination of operations and increased responsiveness to demand variations or production anomalies.

Artificial intelligence (AI) and machine learning are also essential pillars of Industry 4.0. They allow for the analysis of vast amounts of data to detect trends, predict failures, and optimize production processes. For example, machine vision combines advanced camera systems with image recognition algorithms, improving the quality and precision of manufacturing operations.

Collaborative robotics, or cobots, allow robots to work alongside humans, thereby increasing productivity while reducing fatigue and human error. This harmonious collaboration between humans and machines paves the way for more flexible and secure work environments. Additionally, augmented reality (AR) and virtual reality (VR) provide innovative training and maintenance tools, enabling operators to visualize complex information and interact with systems in an immersive way.

Moreover, predictive analytics enables manufacturers to forecast future needs and adjust their strategies accordingly. For instance, in Indonesia, Industry 4.0 has been successfully integrated into the fashion sector, combining sustainability and technological innovation, thus demonstrating the versatility and positive impact of advanced technologies across various industrial sectors.

How does Industry 4.0 strengthen supply chain resilience

Supply chain resilience has become a priority for manufacturers in the face of economic uncertainties and global disruptions. Industry 4.0 offers robust solutions to enhance this resilience through intelligent management and increased visibility across the entire production network.

Through the Internet of Things (IoT) and smart sensors, manufacturers can monitor in real-time the status of their equipment, the location of materials, and the progress of production processes. This granular visibility allows for rapid reaction in case of problems, thus limiting interruptions and ensuring continuity in the supply chain. For example, when a machine detects an anomaly, it can automatically trigger alerts and adjust operations to avoid a major breakdown.

Additionally, advanced data analytics and artificial intelligence enable the prediction of future trends and anticipation of resource needs, thereby optimizing planning and inventory management. This predictive capacity reduces the risks of overstocking or stockouts, ensuring an agile response to market fluctuations. Furthermore, the integration of advanced Enterprise Resource Planning (ERP) systems with Industry 4.0 technologies facilitates optimal coordination among different links in the chain, thereby improving overall efficiency.

Another key aspect of resilience is the ability to diversify and localize supply sources. Industry 4.0 enables more flexible and adaptable manufacturing, where production lines can be quickly reconfigured to meet specific needs or to incorporate new material sources. This flexibility reduces dependence on single suppliers and allows for rapid adaptation in the event of geopolitical or economic disruptions.

What are the tangible benefits for manufacturers integrating Industry 4.0

The integration of Industry 4.0 offers a multitude of tangible benefits for manufacturers, ranging from improved operational efficiency to increased customer satisfaction. One of the main advantages is the optimization of processes, made possible through automation and enhanced connectivity. Intelligent machines and automated systems reduce downtime and minimize human errors, ensuring a smoother and more reliable production process.

Furthermore, data analysis allows manufacturers to make informed decisions based on accurate, real-time information. This ability to analyze operational performance facilitates the identification of bottlenecks and improvement opportunities, leading to better resource allocation and reduced production costs. For example, by adopting a pragmatic approach to integrate existing equipment, manufacturers can modernize their operations without massive investments, thus maximizing the return on investment.

Additionally, Industry 4.0 allows for greater product customization, thereby better meeting specific customer expectations. Flexible production systems can quickly adjust manufacturing lines to produce tailored items, thereby enhancing customer satisfaction and loyalty. This ability to customize products in real-time offers a significant competitive advantage in the market.

Finally, sustainable practices integrated within Industry 4.0 contribute to a more environmentally friendly production process. By optimizing resource use and reducing waste, manufacturers can not only decrease their carbon footprint but also meet the growing demands for corporate social responsibility. For example, the alliance of fashion and Industry 4.0 in Indonesia illustrates how companies can integrate sustainable practices while adopting advanced technologies, creating a beneficial synergy for both the environment and the economy.

What is the future of Industry 4.0 for manufacturers

The future of Industry 4.0 for manufacturers looks promising, with continuous innovations pushing the boundaries of smart production. Increased integration of emerging technologies, such as blockchain for transparent and secure traceability, and digital twins for realistic simulation of production processes, are set to play a key role in the future evolution of the industry.

Additionally, the convergence of AI and edge computing will enable even faster and more autonomous decision-making at the machine level, thus reducing dependence on centralized systems and improving operational responsiveness. This increased autonomy will pave the way for ultra-flexible production environments capable of adapting in real-time to changes in demand and operational challenges.

Furthermore, the growing emphasis on sustainability and environmental responsibility will continue to shape the development of Industry 4.0. Manufacturers will be increasingly encouraged to adopt eco-friendly practices by optimizing energy efficiency and reducing waste, enabled by smart technologies. This trend will not only comply with strict regulations but also strengthen the reputation of companies with consumers who are conscious of environmental impact.

Finally, international collaboration and knowledge sharing will play a crucial role in the evolution of Industry 4.0. Initiatives like the launch of the Industry 4.0 Academy demonstrate the importance of cooperation between the educational and industrial sectors to train a skilled workforce and promote innovation. By fostering a collaborative ecosystem, manufacturers will be able to fully leverage advanced technologies and successfully navigate a constantly evolving industrial landscape.

“`