Supply Chain 4.0 is heralded as a revolutionary catalyst for the manufacturing industry, integrating advanced technologies such as automation, artificial intelligence, and the Internet of Things. These innovations promise not only to optimize supply chains but also to make them more responsive and predictive. With increased visibility gained from real-time data analysis, manufacturers can now anticipate failures and optimize their resources for significant efficiency gains. This digital transformation outlines the contours of a new era where adaptability and resilience become the norms, propelling companies’ competitiveness to new heights.

Supply Chain 4.0 marks a revolution in the manufacturing industry by integrating cutting-edge technologies. Through automation, artificial intelligence, and the Internet of Things (IoT), this new approach modernizes supply chain management. Companies now benefit from real-time visibility and data-driven decision-making. The adoption of predictive strategies helps avoid unexpected disruptions, thus limiting unplanned downtime that costs manufacturers billions annually. Predictive maintenance, supported by sensors and machine learning algorithms, anticipates failures before they occur, thereby reducing costly production interruptions. Furthermore, warehouse management systems provide real-time tracking of inventory, preventing shortages that could halt production. Supply Chain 4.0 enhances efficiency, reduces costs, and boosts performance, shaping the future of a more resilient and competitive manufacturing industry.

Table des matières

ToggleKey technological advances of supply chain 4.0

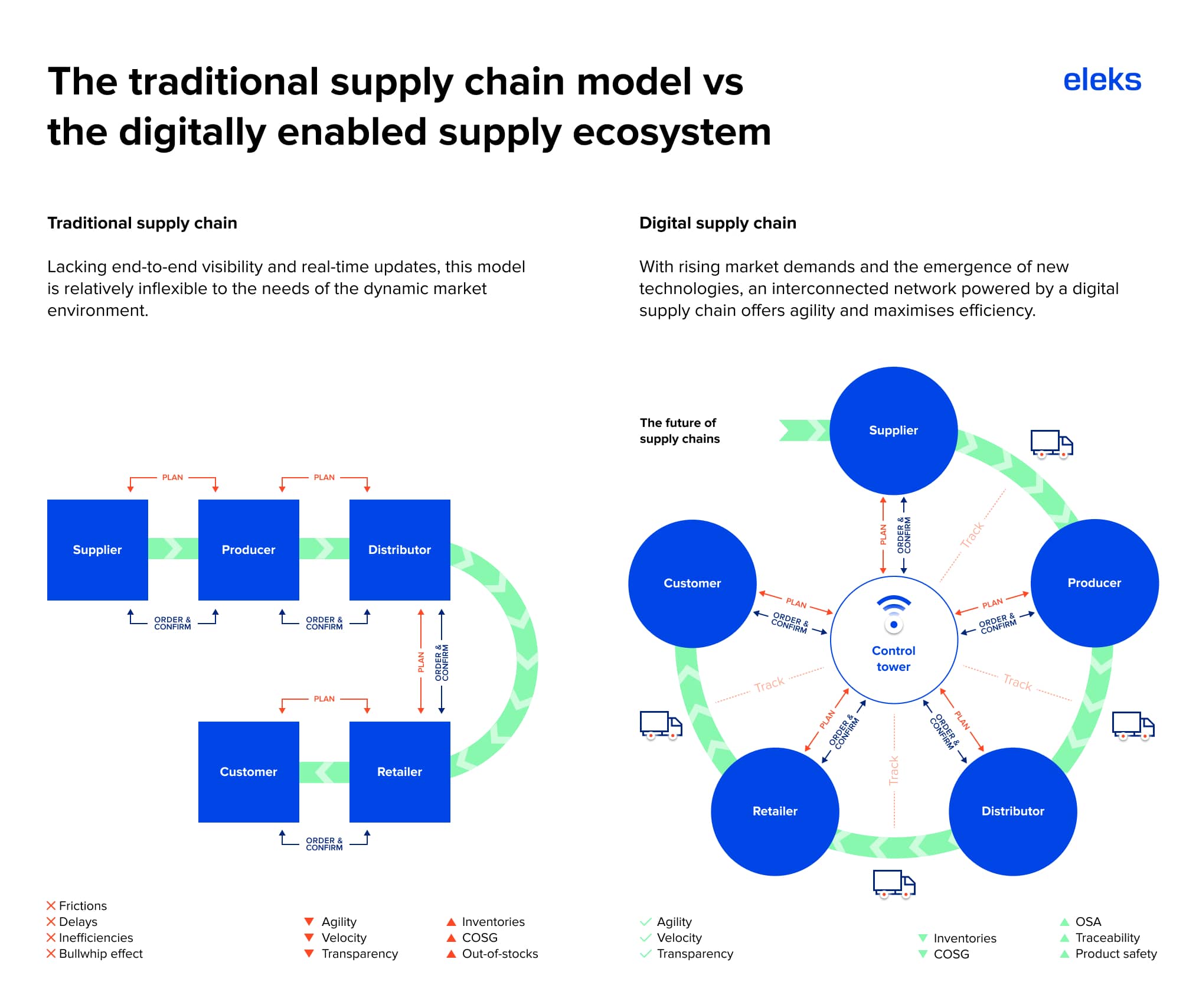

Supply Chain 4.0 is revolutionizing the manufacturing industry through the integration of groundbreaking technologies such as automation, artificial intelligence, and the Internet of Things (IoT). These innovations radically transform traditional supply chains into interconnected and autonomous systems, thereby reducing costs and increasing efficiency. With IoT, every machine and device in a factory can be connected, allowing for an uninterrupted flow of data that feeds real-time analytics. This interconnection contributes to the emergence of new proactive strategies that minimize unexpected production stoppages, a significant challenge for factories worldwide. Learn more about optimizing the supply chain through Industry 4.0.

Economic and ecological benefits

The advancements enabled by Supply Chain 4.0 are not limited to improving internal processes within a company. They also play a crucial role in promoting more sustainable and economically viable business practices. Emerging technologies such as autonomous vehicles and drones help streamline delivery routes, thus reducing fuel consumption and CO2 emissions. Moreover, the intelligent use of data analytics and demand forecasting allows for more effective inventory management, preventing overproduction and waste. In the long term, these savings translate into a significant reduction in transportation and storage costs while enhancing the green image of manufacturers eager to meet the expectations of modern environmentally-conscious consumers.

Organizational culture shift and training

To harness Supply Chain 4.0, a fundamental shift in organizational culture is required within the manufacturing industry. Companies must transition from a traditional approach to one that is oriented towards digitization and data analysis. This shift comes with an urgent need to train the existing workforce and recruit new talents capable of navigating this digital environment. Companies must invest in continuous training to ensure that their employees are not only proficient in using modern technologies but can also anticipate future challenges. Learn more about digital transition.

« From Industry 4.0 to Supply Chain 4.0 » ➡️ Read the opinion article of Alain Frehring, Executive Vice President Purchasing at @SafranLandingS > https://t.co/Bk38hrwZK6 pic.twitter.com/AUnM57PiRf

— Safran Landing Systems (@SafranLandingS) December 4, 2018

“`