Industry 4.0 is booming and generating great economic expectations. With the prospect of reaching over $513 billion by 2031 thanks to the rise of automation, this sector fascinates with the possibilities it offers. But this ambitious projection raises questions about the actual capacity of Industry 4.0 to achieve such figures.

According to SkyQuest, the global market size for Industry 4.0 was estimated at USD 133.05 billion in 2022 and is expected to grow to USD 513.89 billion by 2031, with a compound annual growth rate (CAGR) of 16.2% during the forecast period (2024-2031).

Table des matières

ToggleThe importance of automation and interconnectivity

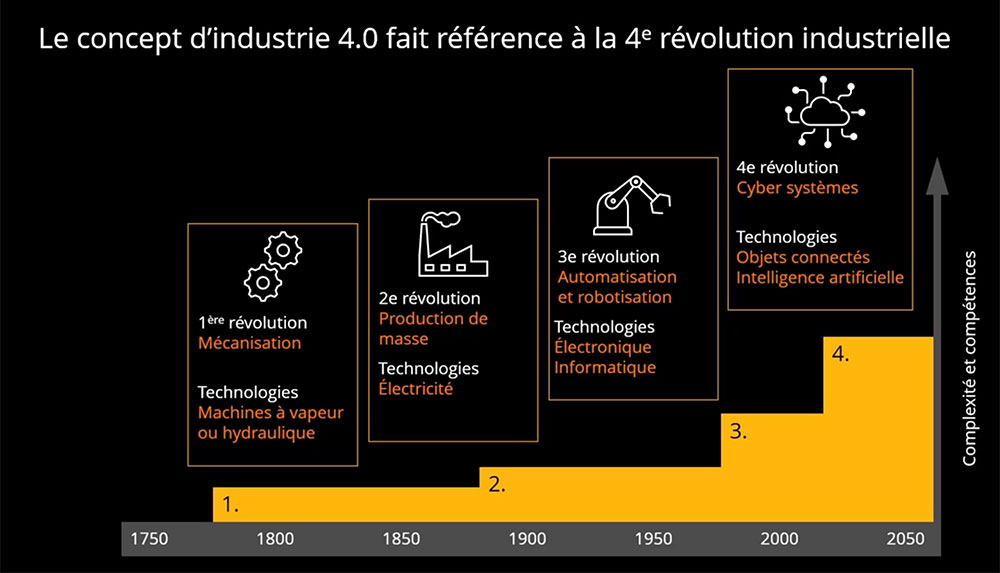

Industry 4.0, or the fourth industrial revolution, emphasizes the use of automation and interconnectivity. By integrating advanced technologies such as artificial intelligence, machine learning, robotics, and connected devices, the industry can improve productivity and efficiency. Rapid digitalization and technological advances will certainly drive the growth of the Industry 4.0 market in the coming years.

Key technologies of Industry 4.0

The following technologies play a major role in the development of Industry 4.0:

- Internet of Things (IoT): Critical for interconnectivity and automation across various sectors.

- Advanced Robots: Increasing adoption and high investments in robotic technologies.

- Artificial Intelligence (AI): Continuous monitoring, real-time analytics, and predictive maintenance.

The adoption of Industry 4.0 in different sectors

The manufacturing sector is leading the adoption of Industry 4.0. The increased use of robotics, advanced technologies, and smart manufacturing practices highlights the importance of this industry. Manufacturers seek to improve efficiency, reduce downtime, and maximize profits.

The automotive industry is also benefiting from the rise of advanced technologies and smart manufacturing practices. The aerospace and defense industry also shows great potential through the adoption of advanced techniques and technologies to create complex components.

Additionally, the oil and gas industry is adopting the Industry 4.0 trend to improve its operations and optimize resource use. The growing demand for predictive maintenance and digital oilfield solutions supports this growth.

Prospects of Industry 4.0

As automation and digitalization progress worldwide, the prospects for Industry 4.0 look very promising. High investments in the development of IoT and AI technologies will create increased opportunities for businesses involved.

The manufacturing sector will remain the main contributor to revenues, but opportunities will also arise in the aerospace, automotive, and oil and gas sectors in the coming years.

| Aspect | Impact on Industry 4.0 |

|---|---|

| IoT | Improvement of interconnectivity and automation |

| Advanced Robots | Increased adoption and reduced margin of error |

| Artificial Intelligence (AI) | Continuous monitoring and real-time analytics |

| Manufacturing Sector | Main contributor to revenues |

| Automotive Sector | Maximization of production |

[#Article] 🤖 Industrie 4.0 : le start-up studio @OSSVentures annonce une levée de fonds de 8,5 millions d’euroshttps://t.co/NTh6V1deXS #IA #IntelligenceArtificielle

— Actu IA – Intelligence Artificielle (@ActuIAFr) June 28, 2024