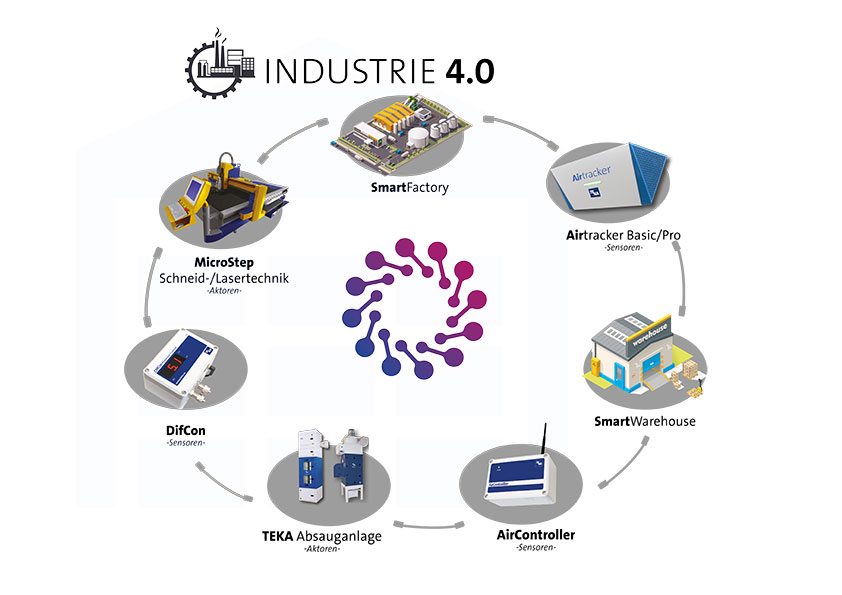

At the dawn of a new technological era, Industry 4.0 stands out as a revolution that disrupts the very foundations of traditional production. A bridge between the physical and virtual worlds, this evolution embodies a transformation where cyber-physical systems play a central role, rethinking how companies interact with their manufacturing processes. By integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence, and data analytics, Industry 4.0 paves the way for smart factories capable of automating and optimizing operations in real-time. This innovative model is not limited to simple automation; it also invites a rethinking of human interactions within companies. In this context, understanding the implications and potential of cyber-physical systems becomes essential to grasping this global transformation. Furthermore, Industry 4.0 signifies not only increased productivity but also a dynamic of innovation and sustainability, going well beyond what we have experienced during previous industrial revolutions.

Table des matières

ToggleIndustry 4.0: A Deep Dive into the Fourth Industrial Revolution

The concept of Industry 4.0 refers to the profound transition of the industry, driven by the advent of advanced technologies such as the Internet of Things (IoT), artificial intelligence, and big data systems. According to a McKinsey study, 70% of companies plan to integrate these new technologies by 2025. This represents a new era, where the integration of cyber-physical systems transforms production chains, logistics systems, and even human resource management.

Cyber-physical systems (CPS) are at the heart of this revolution. They involve a systemic approach that allows software and machines to communicate and interact autonomously. This concept is not new, but it takes on an unprecedented dimension within the framework of Industry 4.0. For instance, factories in Germany are utilizing CPS to optimize production and reduce delivery times, achieving a 20% reduction in operational costs in just two years.

Tangible Benefits of Industry 4.0

Adopting Industry 4.0 is not just about following a technological trend; it is about realizing concrete gains. Consider the automation of processes: a Deloitte study revealed that companies that have integrated automation solutions reported a 40% improvement in their efficiency. By applying real-time data, they are able to anticipate customer demands and dynamically adjust their production.

A demonstrative example is Siemens, which has implemented a model of smart manufacturing where each machine is connected via sensors and algorithms. By collecting and analyzing data, the company can predict machine failures and maintain its equipment proactively. This case illustrates how Industry 4.0 promotes not only efficiency but also sustainability, by reducing waste and extending the lifespan of operations.

Challenges and Perspectives: How to Navigate this New Era

Although the benefits are appealing, the transition to Industry 4.0 is not without challenges. Companies must be ready to overcome barriers such as the lack of skills in cybersecurity and reluctance to organizational change. A recent PwC survey shows that 60% of executives fear that cybersecurity will hinder digital transformation. It is essential to develop strategies to mitigate these concerns, by investing in training and adopting a proactive approach to data security.

In parallel, collaborative innovation should be encouraged. In this regard, the Manufacturing X initiative in Germany has established a standard for collaboration between various industries, allowing knowledge and best practices to be shared. For companies wishing to involve their teams in this transformation, it is recommended to set up collaborative workshops aimed at identifying solutions based on employees’ feedback.

Thus, Industry 4.0 is not merely a technological evolution; it requires deep reflection on how to structure our organizations to meet the challenges of tomorrow. It is a transformation that demands visionary leaders ready to embrace change and foster a culture of continuous innovation. It calls for us to reinvent ourselves, both at the employee level and in processes, in order to remain competitive in an ever-changing global market.

FAQ about Industry 4.0 and Cyber-Physical Systems

What is Industry 4.0? Industry 4.0 represents the fourth industrial revolution characterized by the integration of digital technologies in production processes, making factories smarter and more connected.

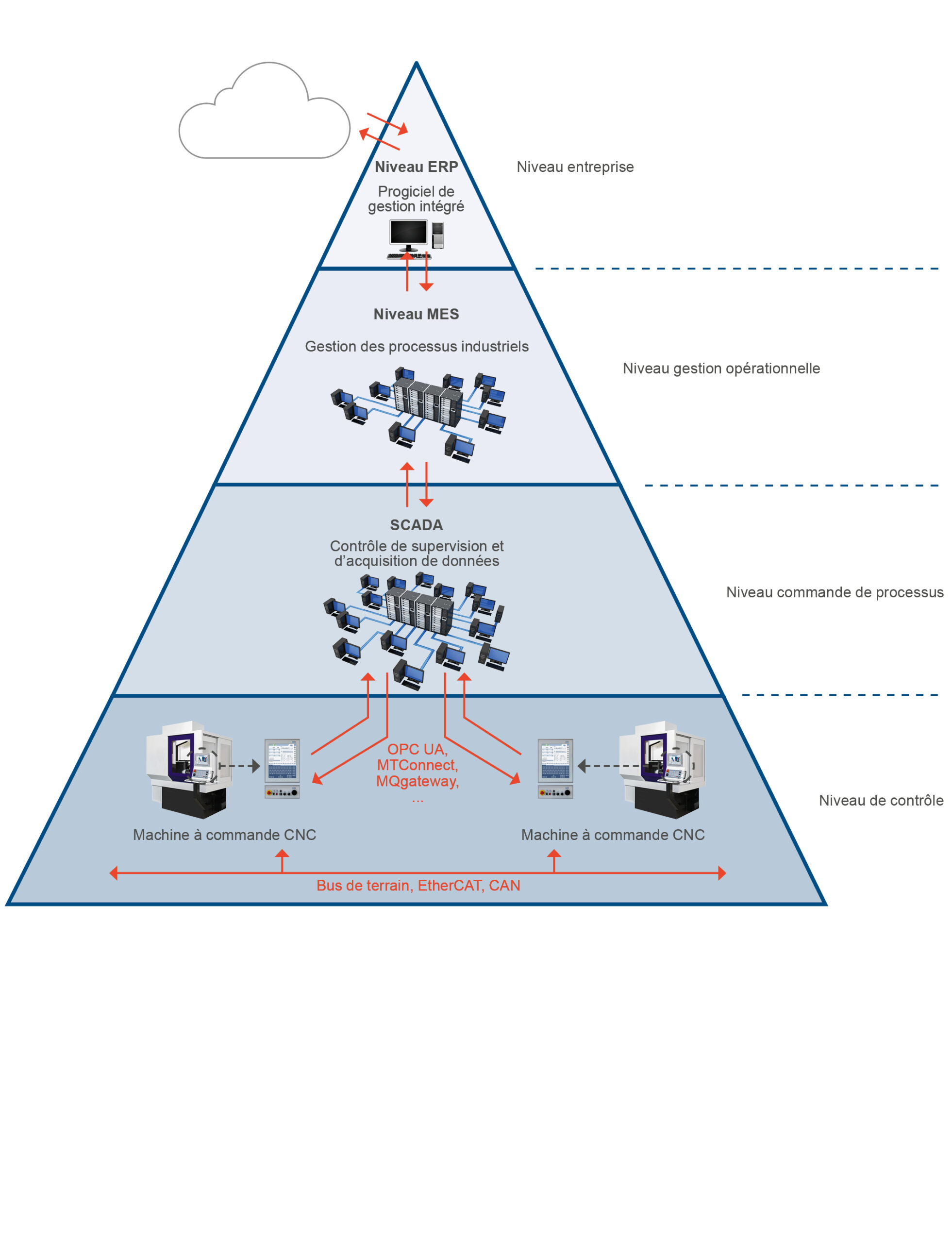

What are the benefits of cyber-physical systems? Cyber-physical systems enable autonomous communication between machines, improve process management, and contribute to the optimization of resources through real-time data.

How does Industry 4.0 improve operational efficiency? By integrating intelligent and connected systems, Industry 4.0 allows companies to reduce costs, increase productivity, and quickly adjust their processes based on demand.

What are the key components of Industry 4.0? Essential components include the Internet of Things (IoT), cyber-physical systems, automation, and advanced analytics to manage the complexity of modern production.

Why is it important to adopt Industry 4.0? Adopting Industry 4.0 is crucial for remaining competitive in the market, meeting consumer demands, and leveraging new technologies to innovate continuously.

Can cyber-physical systems operate autonomously? Yes, cyber-physical systems exchange information and make decisions autonomously, allowing them to manage complex processes without direct human intervention.

What challenges does Industry 4.0 present? Challenges include the migration to advanced digital systems, the training of employees, and the need to ensure the cybersecurity of connected systems.

How can companies prepare for Industry 4.0? Companies should start by assessing their current infrastructures, investing in training staff, and gradually adopting digital solutions tailored to their industry.