In the world of modern manufacturing, rethinking the efficiency and quality of processes is a necessity. Mr. IIoT positions itself as a pioneer in this approach, providing industrial players with tailored digital transformation services. The integration of advanced technologies such as IoT and automation allows for a true revolution. This personalized approach ensures a smooth adoption of innovations from Industry 4.0, thereby supporting a sustainable improvement in industrial performance.

Mr. IIoT positions itself as an innovative leader in the digital transformation of industries. Its advanced systems integration services modernize manufacturing processes by utilizing the latest technologies of Industry 4.0. Faced with the need to improve efficiency, reduce downtime, and enhance product quality, Mr. IIoT offers customized solutions to integrate the appropriate digital technologies. This personalized approach encourages competitiveness in a constantly evolving market.

Committed to optimizing manufacturing operations, Mr. IIoT offers comprehensive services including the integration of IoT devices, data analysis, and automation. The tailored solutions enable companies to unleash the full potential of digital transformation to streamline their operations, reduce costs, and enhance their competitiveness.

Table des matières

ToggleMr. IIoT’s services for tailored digital transformation

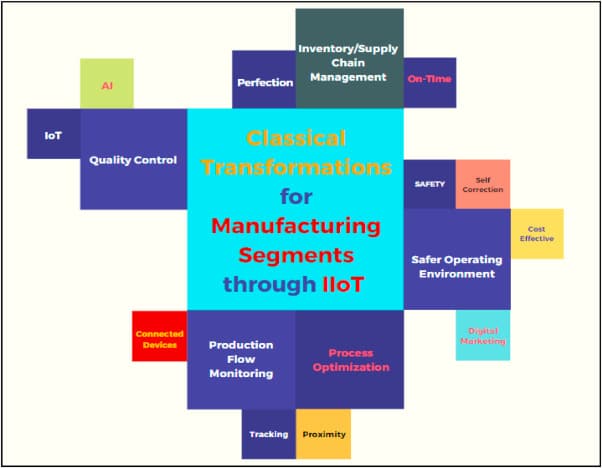

Mr. IIoT positions itself as a key player in the transition to Industry 4.0, offering customized digital transformation services. With the integration of advanced technologies such as Industrial Internet of Things (IIoT) and artificial intelligence (AI), each solution is tailored to meet the specific needs of each client. By optimizing production processes through connected devices and sensors deployed on production lines, Mr. IIoT helps companies improve their operational efficiency. To learn more about the impact of IIoT on Industry 4.0, explore connectivity at the service of Industry 4.0.

The solutions offered range from integration of IoT devices to data analysis and industrial automation. By using cutting-edge tools, Mr. IIoT creates intelligent networks within factories that allow for real-time monitoring and control. This not only reduces machine downtime but also improves product quality, thereby consolidating the competitive position of client companies. Customization is key, enabling businesses to fully leverage the benefits of digital transformation. For a better understanding of current strategies, check this overview of digital revolutions.

customization and integration of innovative solutions

In today’s industrial context, the customization of services is essential for successful adaptation. Mr. IIoT stands out with its tailored approach that takes into account the unique goals and challenges of each company. By developing personalized digital transformation strategies, they ensure that each client benefits from the most relevant technology for their sector. The integration of these solutions is not limited to installing new devices; it includes ongoing training and technical support to maximize the use of newly implemented systems and to ensure smooth adoption by all employees.

towards a more agile and sustainable industry

The transformation to Industry 4.0 is not just about improving productivity; it also aims to enhance the sustainability and agility of operations. Mr. IIoT is committed not only to optimizing production but also to promoting more sustainable practices through the intelligent use of energy. Through in-depth analysis of data collected by IoT sensors, they can identify areas of energy waste and propose solutions to address them. This leads to a reduction in carbon footprint while maintaining optimal operational efficiency. To discover how this approach shapes the future of industry, read this case study on Siemens and its impressive results.