In the current context, companies in Maine find themselves at a crucial crossroads where the adoption of Industry 4.0 could be decisive for their future. A recent study from the Northeast highlights the urgency of integrating automation and real-time data into decision-making processes. This digital transformation, already well underway internationally, offers opportunities to improve productivity, wages, and the quality of life of workers. The transition to smart manufacturing practices could very well be the key to the regional, national, and global success of local businesses.

A recent study led by Jack Lesko, an engineering professor at Northeastern University in Portland, emphasizes the urgency for companies in Maine to adopt Industry 4.0. This concept of the Fourth Industrial Revolution focuses on the integration of automation and real-time data collection into decision-making processes. Lesko asserts that these technologies can enhance productivity, increase wages, and improve the quality of life for workers. In response to international trends, the digitization of businesses in Maine appears crucial for strengthening their success at both regional and global levels. The study, supported by the Maine Technology Institute, also underscores the need for an independent assessment and action plan to better integrate these technological advancements. The goal is to transform new technologies into assets rather than threats, thus enabling an effective response to modern economic challenges.

Table des matières

ToggleThe Challenges of Adopting Industry 4.0 in Maine

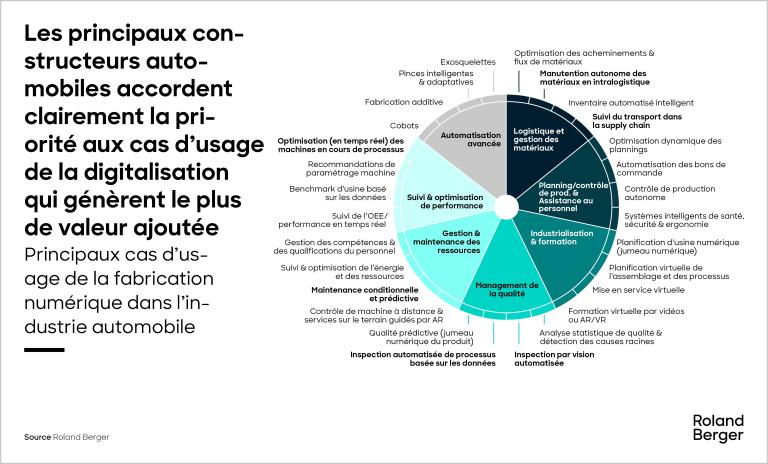

Companies in Maine face major challenges in adopting Industry 4.0, a concept that promises radical transformation through the integration of digital technologies into manufacturing processes. A recent study conducted by the Roux Institute highlights the lack of awareness among industrial leaders in Maine regarding this fourth industrial revolution. This poses a significant hindrance to their competitive chances at the regional, national, and global levels. Nevertheless, the ability to turn data into informed decisions could offer them invaluable competitive advantages.

The Importance of Data in the New Industrial Era

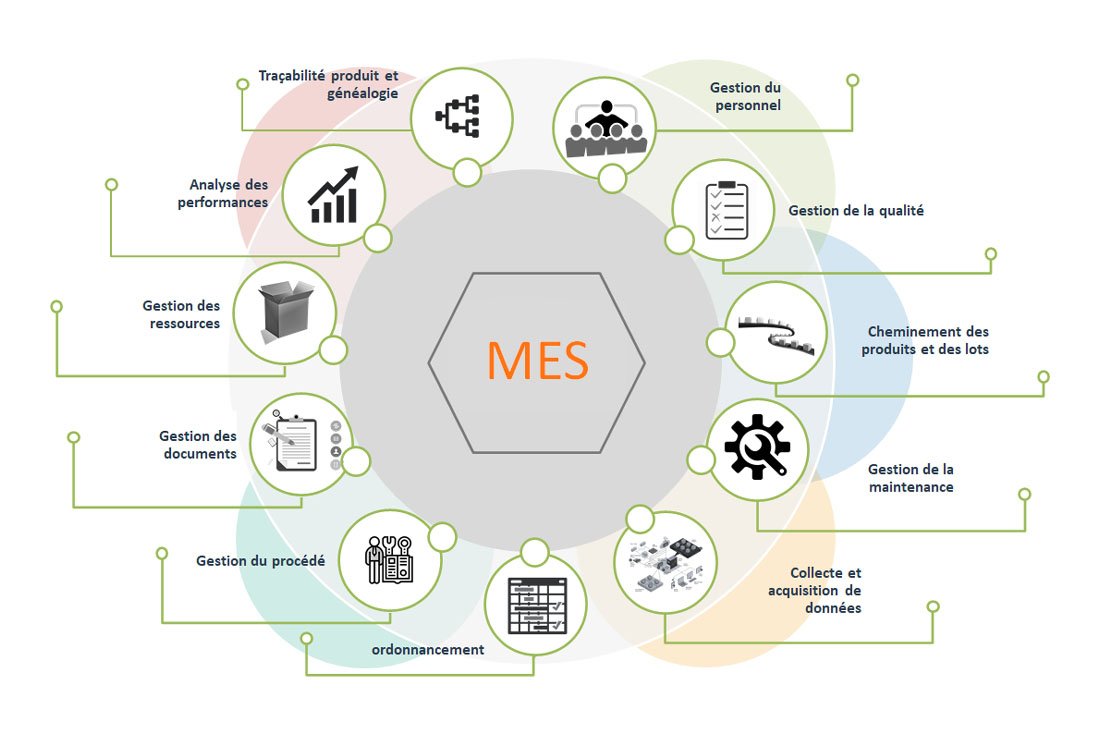

Currently, many companies in Maine do not fully grasp the crucial importance of data in modernizing their operations. Adopting the principles of Industry 4.0 is much more than just integrating new technologies; it involves rethinking organizational culture to place greater emphasis on real-time data analysis. Leaders must recognize that this transformation is not only about machines and software but also about elevating human engagement in critical decision-making processes.

Strategies for a Successful Transition

For companies in Maine to successfully transition to Industry 4.0, it is beneficial to conduct an independent and impartial evaluation of their current practices. Involving certified experts from the Roux Institute can help develop an effective roadmap for utilizing data meaningfully. By adopting an integrated approach that considers culture, leadership, and existing quality systems, companies can hope for a significant improvement in productivity and increased resilience in the face of potential disruptions.