In an environment where speed and efficiency are essential, the optimization of industrial processes has become an unavoidable necessity. Industrial cloud, with its innovative characteristics, is revolutionizing the way companies manage their operations. By relying on virtual resources, this model allows for real-time monitoring of every aspect of production, identifying potential issues before they impact the operational chain. Thanks to its flexibility, the integration of this system becomes an easy reality, making accessible the analysis of relevant data for informed strategic choices.

On the other hand, process automation, facilitated by sophisticated software, increases productivity while reducing operational costs. This means that companies can focus on higher value-added tasks while relying on precise data to make crucial decisions. Thus, the industrial cloud stands out as an indispensable ally for businesses seeking not only to survive but to excel in an increasingly competitive market.

In the age of digital transformation, industrial process optimization has become a necessity for companies looking to improve their operational efficiency. The industrial cloud represents an innovative solution to address these challenges. It offers flexible and scalable tools that enable the integration of advanced technologies such as real-time data analytics, process automation, and machine learning. This section will explore the advantages and potential of optimization through the industrial cloud, relying on recent data and specific case studies.

Table des matières

ToggleThe Economic and Operational Benefits of the Industrial Cloud

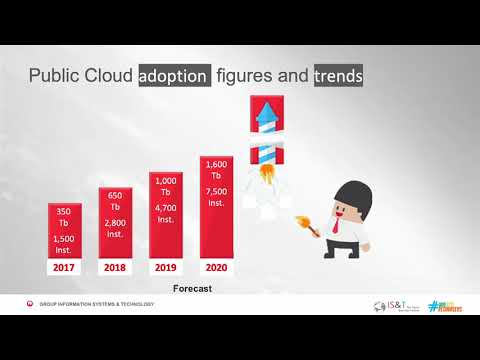

A market report published in 2022 estimates that the industrial cloud sector is expected to grow by 25% per year, driven by increasing needs for flexibility and digitization. This trend demonstrates the importance of this approach for companies eager to optimize their production chain. The implementation of cloud solutions allows, among other things, to reduce IT infrastructure costs, improve data access, and facilitate collaboration among teams.

A concrete example is that of an automotive factory in Spain that integrated a cloud solution to monitor its production lines. Thanks to this technology, the company was able to detect bottlenecks in its manufacturing process, resulting in a 30% reduction in downtime. By using data analytics platforms, it was able to analyze performance in real time, enabling informed and rapid decision-making.

Volkswagen ouvre son projet de cloud industriel à tout un réseau de partenaires https://t.co/t6BUQiHQQx pic.twitter.com/UvM0mjcu0S

— Jean-Louis JOUVE (@LouisJouve) July 25, 2020

Practical Strategies for Integrating the Industrial Cloud

To fully benefit from the advantages offered by the industrial cloud, it is essential to follow certain practical strategies. Here are some key recommendations:

- Develop a clear roadmap: Before diving into cloud integration, assess your needs and establish a roadmap detailing your short-term and long-term goals. This will ensure a smooth and well-thought-out transition.

- Prioritize process automation: Automation is one of the main levers for optimizing costs and improving efficiency. Invest in software solutions capable of managing manual processes automatically.

- Provide appropriate training: To get the most out of cloud tools, regular training tailored to your teams is essential. This will help enhance skills and reduce resistance to change.

- Monitor performance in real-time: Integrate real-time monitoring systems to track the progress of processes. This will allow for early identification of problems and increased responsiveness.

An illustrative example of successful implementation is that of a leading player in the food industry that migrated to a cloud solution. By automating its inventory management through a system based on machine learning algorithms, the company observed a 20% increase in logistical efficiency and a significant reduction in food waste.

Future Landscapes: Innovation with the Industrial Cloud

The innovation prospects offered by the industrial cloud are vast. Concepts like the Internet of Things (IoT) and artificial intelligence (AI) combine with cloud capabilities to create smart ecosystems. By integrating connected devices into the production loop, companies can gather valuable data that, when analyzed by AI tools, allow for proactive optimization of operations.

Moreover, the advent of 5G opens new possibilities for the industrial cloud in terms of fast and reliable communication between devices. Practical application scenarios include augmented reality for machine maintenance, where a technician equipped with special glasses can receive real-time information from the cloud, thereby enhancing performance and speed of interventions.

Finally, recent initiatives, such as those from OpenAI, demonstrate a clear intent to integrate advanced AI software into the industrial cloud, contributing to significant advancements in cost optimization. These innovations not only improve performance but truly transform the vision of industry 4.0.

In summary, the industrial cloud is not just a simple technological solution. It is a strategic lever to optimize your industrial processes and propel your company towards maximum efficiency.

FAQ on Optimizing Processes with the Industrial Cloud

What is optimization with the industrial cloud? Optimization with the industrial cloud involves using cloud-based technologies to improve operational efficiency, reduce costs, and increase the flexibility of industrial processes.

What are the benefits of using the industrial cloud? Benefits include better visibility into operations in real-time, greater flexibility, and a reduction in costs through automation and effective resource management.

How can the cloud help prevent production problems? Through advanced analytics tools and continuous monitoring, the cloud can identify and anticipate anomalies before they lead to production interruptions.

What types of data can be collected in a cloud environment? In a cloud environment, real-time data can be collected on machine performance, production timelines, and many other key performance indicators for informed decision-making.

Is automation necessary in the industrial cloud? Yes, automation is essential to maximize the benefits of the cloud, as it minimizes human errors, improves productivity, and reduces downtime.

Is the industrial cloud secure? Industrial cloud solutions are designed with robust cybersecurity measures to protect sensitive data from external threats while ensuring regulatory compliance.

How to encourage employees to adopt the industrial cloud? To promote this adoption, it is important to provide appropriate training, communicate the benefits of the cloud, and create a collaborative work environment that makes using the cloud appealing.

Which industries can benefit from the industrial cloud? Many sectors, such as manufacturing, logistics, and automotive, can greatly benefit from cloud solutions to optimize their processes and improve their productivity.