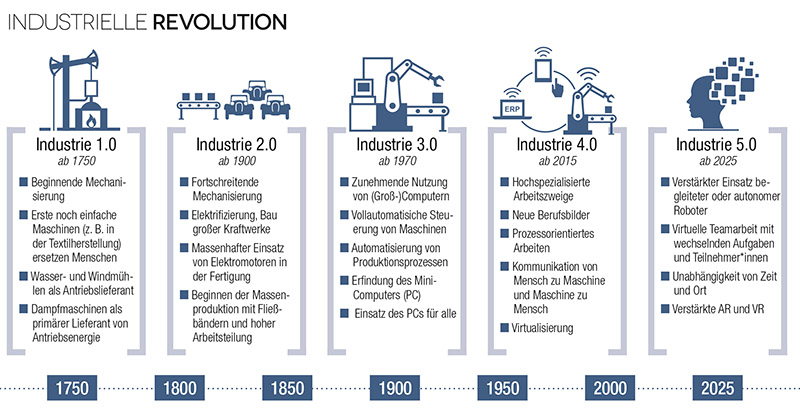

Imagine a time when technology and humanity coexist harmoniously at the heart of production chains. This is the essence of Industry 5.0. This industrial revolution, much more human and sustainable, relies on rigorous planning, robust strategies, and open communication. The integration of the human element with intelligent machines transcends traditional automation to give birth to factories where digital transformation combines with human expertise, making businesses more resilient and efficient.

Industry 5.0 represents a human-centered industrial revolution, adding a crucial human dimension to Industry 4.0. To establish a solid foundation for this transformation, it is essential to implement rigorous planning, robust strategies, and foster open and inclusive communication. Industry 5.0 aims to achieve effective integration between humans and intelligent technologies, while making businesses more sustainable and resilient. By encouraging the active role of workers and adopting advanced automation technologies, such as artificial intelligence and machine learning, this model revolutionizes industrial production toward a more human and technological future.

Table des matières

ToggleUnderstanding Industry 5.0

Industry 5.0 marks a crucial step where technology and humanity no longer operate in parallel but in symbiosis. Unlike Industry 4.0, which primarily focused on automation and cyber-physical systems, Industry 5.0 emphasizes the importance of human interactions while integrating technologies such as artificial intelligence and machine learning.

In this revolution, humans are not merely operators but a central and strategic element. It involves maximizing human capabilities by combining them with intelligent automation technologies. This makes work environments more intuitive and innovative. The adaptability and resilience of workers are also enhanced by this integration, resulting in a more sustainable and holistic industry. For more information on this integration, visit this article.

Key Components of the Transformation

The implementation of Industry 5.0 requires a well-structured approach. Planning must include strong strategies and a robust technical foundation to support new innovations. Open and inclusive communication is also crucial, as it allows for addressing the needs and skills of workers while optimizing interaction with machines. Diagnostic tools for assessing business needs can assist in this regard.

Production chains are becoming increasingly connected and digitized, transforming working conditions. Industry 5.0 pushes this digitalization to a higher level by using intelligent technologies capable of autonomous learning and by integrating the human factor more deeply. Companies must adapt to these changes to remain competitive and relevant in the market. A detailed guide is available in this article.

Strategies for Successfully Transitioning

To successfully transition to Industry 5.0, it is imperative to implement strategies that value human resources. Predictive maintenance and the effective use of resources are two essential aspects that can not only reduce costs but also improve production quality. Companies must invest in the ongoing training of their employees so that they can work with sophisticated automated systems while leveraging their unique human skills.

The integration of technologies such as augmented reality can significantly enhance training and maintenance in the industry. It allows workers to access real-time information and solve problems more effectively. To further prepare for and execute this transformation, discover these innovative strategies.

Vous souhaitez découvrir l'industrie 5.0? retrouvons-nous le 25 mai matin @ArtsetMetiers_ de Lille

— CITC-EuraRFID (@IOTcluster) May 4, 2023

Venez découvrir et tester les #démonstrateurs, l'homme au centre du processus de production

👉https://t.co/EVEPaWWXtt@MetropoleLille @hautsdefrance pic.twitter.com/Pp3Ol5DiQt