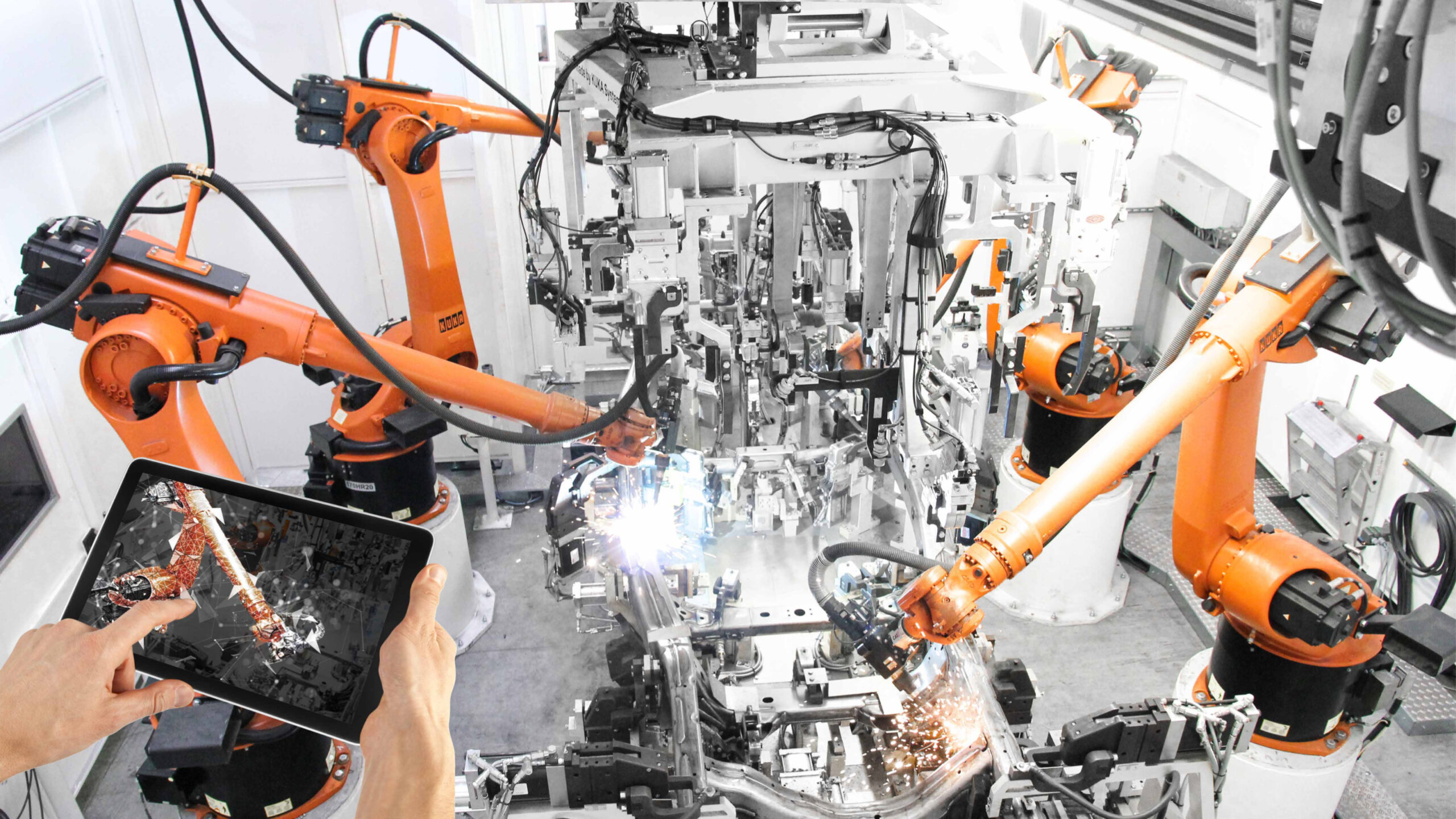

The revolution of the market in Industry 4.0 is underway, disrupting traditional manufacturing methods through the integration of advanced digital technologies. With the growing adoption of the Internet of Things (IoT), artificial intelligence, and automation, factories are transforming into connected and intelligent environments.

These technologies enable greater efficiency and flexibility in production processes while offering better control and a quick ability to adapt to market demands. Through the analysis of big data generated by various sources, companies can now optimize their operations and anticipate production needs with more accuracy.

Advancements such as digital twins, augmented reality, and enrich the industry toolset, allowing for unprecedented customization and innovation in product development.

Table des matières

ToggleDigital Revolution and Industry 4.0

The industrial revolution continues to transform, and the era of Industry 4.0 marks a new stage with the integration of advanced digital technologies. By adopting solutions such as the Internet of Things (IoT), artificial intelligence, and digital twins, the manufacturing sector is revolutionizing its processes. This digital transition enhances productivity, optimizes operational efficiency, and reduces errors, while providing increased visibility across the entire value chain. Smart sensors and data analysis play a crucial role in this change by providing real-time insights that enable more informed and rapid decisions.

Furthermore, recent technological advancements encourage mass customization, a trend that relies on flexible and interconnected systems. Advanced automation, coupled with additive manufacturing, allows for rapid adaptability to consumer wishes. These innovations not only reduce production times and costs but also support sustainability, an essential aspect of the modern economy. The impact of digital technologies in this context is undeniable, and their adoption has become a necessity for companies looking to remain competitive in an ever-changing global market.

Integration of Systems and Smart Manufacturing

The key to Industry 4.0 lies in the seamless integration of systems and the ability to turn real-time data into concrete actions. Smart supply chains, enhanced by blockchain, ensure greater transparency and traceability, essential in an economy where regulatory compliance and customer requirements are becoming increasingly stringent. Technologies like 3D printing, transforming prototyping and small batch manufacturing, enable accelerated product development.

At the same time, the integration of digital technologies enhances resilience against disruptions and increases operational flexibility. This capacity for adaptation is crucial for agile management of demand fluctuations and unforeseen challenges. Through these interconnected systems, companies can optimize their performance, mitigate risks, and anticipate future trends. The omnipresence of digital technologies thus reconfigures how businesses collaborate and innovate in a constantly evolving networked world.

Challenges and Opportunities in Industry 4.0

Advanced digital technologies bring considerable opportunities to propel smart manufacturing in Industry 4.0, but they also come with significant challenges. Companies must navigate a competitive landscape where constant innovation is essential to maintain a dominant position. Heavy investments in technological infrastructure and growing concerns regarding cybersecurity pose potential obstacles to the widespread adoption of these innovations. However, by overcoming these challenges, the industry can benefit from improved productivity, shorter manufacturing cycles, and increased product customization, thus meeting the expectations of increasingly connected and demanding customers.

Continuous training of staff also becomes a critical issue to ensure that employees are aligned with the new skills necessary for the digital age. The demand for a highly skilled workforce in data manipulation and analysis presents training challenges that industries must address. These efforts to update skills not only foster innovation but also enhance employee engagement, preparing them to work alongside evolving technologies that redefine production processes.