Industry 4.0 embodies a major transformation with the promise of connected and intelligent factories. At the heart of this technological revolution, Artificial Intelligence emerges as a significant ally to address the critical challenges of the sector, notably the talent shortage. KCF Technologies, led by Dr. Jeremy Frank, is exploring the horizons of AI to bridge the workforce gap by making industrial processes more efficient and providing immersive training for young talents. Unlike traditional methods, these innovations encompass a variety of approaches that optimize machine health and reinvent how industries operate. An unparalleled opportunity that could shape the future of industrial jobs.

In the face of a significant labor shortage in the American manufacturing sector, Dr. Jeremy Frank, CEO of KCF Technologies, emphasizes the importance of integrating artificial intelligence to tackle this challenge. In the podcast “Disruption Interruption,” he explains how cutting-edge technology can bridge the skills gap, optimize machine health, and provide sustainable transformation in the industry. As the sector may face 2.1 million unfilled positions by 2030, the focus is on leveraging AI. This allows for transforming operational processes, training, and engaging young talents. According to Dr. Frank, with the right technology, inefficiencies due to imperfect maintenance, complex operating conditions, or inappropriate configurations can be drastically reduced, thereby enhancing the capacity of current workers.

Table des matières

ToggleRevolutionizing Industry 4.0 with KCF Technologies’ AI

Faced with a critical labor shortage, Industry 4.0 anticipates a massive transformation through artificial intelligence. Dr. Jeremy Frank, at the helm of KCF Technologies, proposes innovative solutions to fill skill gaps. By leveraging digital tools and advanced technologies, KCF contributes to faster and more effective training, reducing the necessity for prolonged hands-on experience on the field. The impact of these technologies extends beyond improving productivity to better management of machine health, a facet often neglected but crucial in reducing unexpected downtime and optimizing industrial performance.

When AI is properly harnessed, it unleashes new capabilities within teams, transforming potential challenges into growth opportunities. KCF Technologies accomplishes this by collecting and channeling data related to operations to optimized decision-making platforms. This approach not only improves efficiency but also makes the workplace safer, anticipating risks and facilitating smoother adaptations to the changing standards of the industrial sector. This change is driven not just by technology but by a vision oriented toward a future where humans and machines coexist in a harmonious and productive manner.

The Importance of Cultural Change in Industry

A major challenge remains: attracting new generations to industrial careers. Dr. Frank highlights an obvious yet often overlooked fact — job offerings in industrial sectors no longer attract as they once did. To remedy this, it is crucial to change our perception of manufacturing jobs. These professions offer significant financial benefits and genuine advancement opportunities. These roles take on a deeper meaning as young people become aware of their impact on the real world, far beyond the appealing yet sometimes fleeting tech sector.

To trigger this cultural change, the effort must not be limited to material or financial aspects. Companies must invest in engaging and dynamic strategies to educate and motivate new recruits. In doing so, they will contribute to greater recognition and appreciation of industrial know-how, essential to any advanced society, while also reinforcing the continuity and sustainability of their operations over time.

AI at the Service of Industrial Efficiency

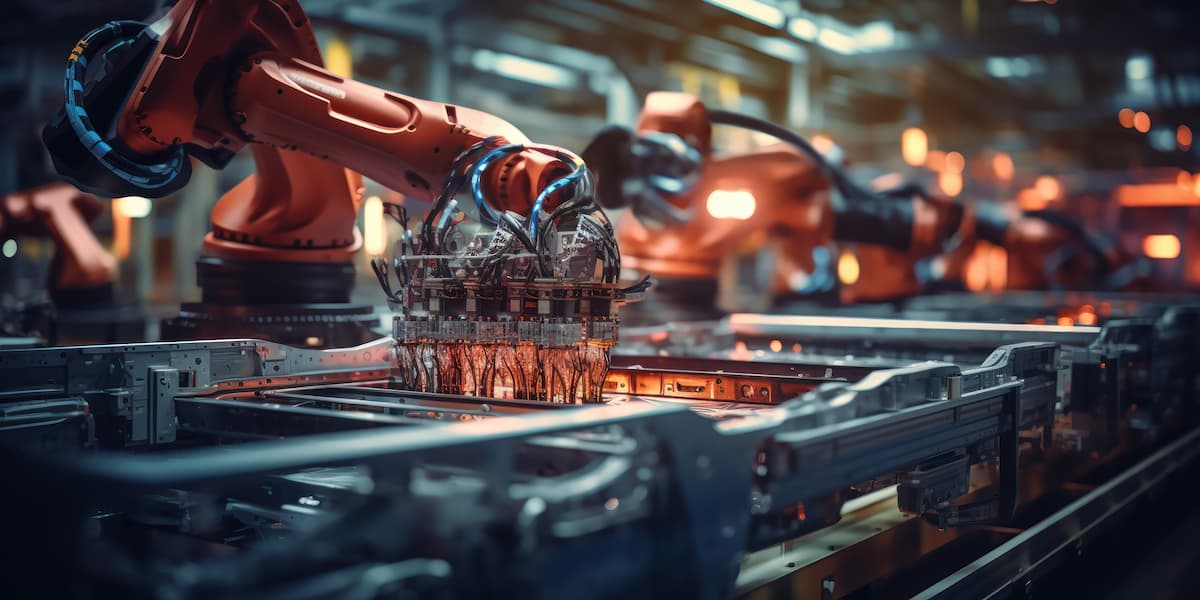

In the context of Industry 4.0, the introduction of AI-based solutions by KCF Technologies has sparked a true revolution in machine health. Dr. Frank explains that understanding the root causes of wear is not trivial. Indeed, machines are subjected to a complex set of operating conditions, often unpredictable. Through the judicious use of AI, it is now possible to obtain precise insights into operational conditions, thereby helping to optimize efficiency.