Imagine a production where every task is carried out smoothly, from machines to operators, including data management. Industrial automation stands out as the ideal solution to turn this dream into reality. By integrating automated systems at the heart of your industrial processes, you not only optimize productivity but also ensure increased safety and more effective cost management. Downtimes are reduced, human errors minimized, and resources are better utilized.

In this quest for efficiency, discovering how automation can simplify your production chain becomes essential. Through advanced technologies, such as smart software and connected machines, every step of production is enhanced. This allows companies not only to respond quickly to market demands but also to continuously adapt to technological changes. Implementing smart automation positions your company at the forefront of innovation, enabling you to explore new growth opportunities.

Industrial automation represents a significant advance in the field of production. By integrating automated systems into operational processes, companies can not only increase their efficiency but also radically transform the way they operate on a daily basis. The main objective of automation is to streamline tasks, optimize performance, and offer unparalleled flexibility in facing market demands.

Table des matières

ToggleThe measurable benefits of automation

Recent statistics show that up to 70% of manufacturing companies have integrated automation technologies into their production chains. According to a study conducted in 2021, companies that adopted automation saw a 30% increase in their productivity while significantly reducing human errors. This reality demonstrates the positive impact of automation on overall performance.

For example, an interesting case study comes from a food processing company that struggled to meet growing demand. By integrating a dynamically automated system, it was able to triple its production throughput while reducing resource waste by 25%. Such remarkable results illustrate the power of this technology to renovate sometimes closed and rigid processes.

Practical recommendations for successful implementation

To fully benefit from automation, it is crucial to adopt a systematic approach. Here are some practical recommendations for a smooth transition to an automated system:

- Needs assessment: Analyze the weaknesses in your production chain to determine where automation can have the greatest impact. Identify repetitive and time-consuming tasks that could benefit from automation.

- Choosing the right technologies: Research the automated systems available on the market. Opt for solutions compatible with your existing infrastructure and capable of evolving with your future needs.

- Employee training: Invest in ongoing training for your staff. Ensure that your teams understand the new technologies and are capable of using them effectively.

Another innovative strategy is to adopt an integrated platform capable of collecting and analyzing production data in real-time. This allows processes to be quickly adjusted to maximize results without requiring frequent manual interventions.

The challenges of transitioning to automation

Despite the numerous advantages of automation, the transition poses challenges. Recent surveys reveal that nearly 40% of companies hesitate to invest in automation due to fears related to initial costs and potential disruptions during implementation. Thus, it is essential to carefully prepare for this transition by developing an action plan that includes testing phases and continuous adjustments.

Companies can also benefit from collaborating with automation experts to minimize the risks associated with change. By partnering with technology solution providers, they can develop a realistic timeline and adjust their strategy based on evolving needs and observed results.

In conclusion, simplifying production through industrial automation is not just a trend but a necessity to maintain levels of competitiveness that are useful in the long term. By following practical recommendations, anticipating challenges, and committing to a path of continuous transformation, companies can hope to not only improve their productivity but also create a more dynamic and attractive work environment for their employees.

Connaissez-vous les différents niveaux d'automatisation de la conduite ?

— Mobilité Club France (@MobiliteClubFR) May 28, 2024

Il existe 6 niveaux au total.

🎬 Découvrez le niveau 3

Pour en savoir plus sur le concept Hi-Drive, rendez-vous sur : https://t.co/wFyrykOiEG.

#HiDriveProject #ConduiteAutomatisée @FIARegionI @_HiDrive_ pic.twitter.com/P7rKBM13A1

FAQ

What is industrial automation? Industrial automation refers to the use of control systems to manage equipment in factories, boilers, heating networks, lighting systems, security systems, and other applications. It aims to improve efficiency, quality, and safety while reducing costs.

What are the main advantages of industrial automation?

- Increased efficiency: Reduction of downtimes and increase in productivity.

- Improved quality: Standardization of processes, which helps reduce errors.

- Enhanced safety: Reduced human intervention in hazardous environments.

- Cost savings: Reduction in labor and operating costs.

What types of technologies are used in industrial automation?

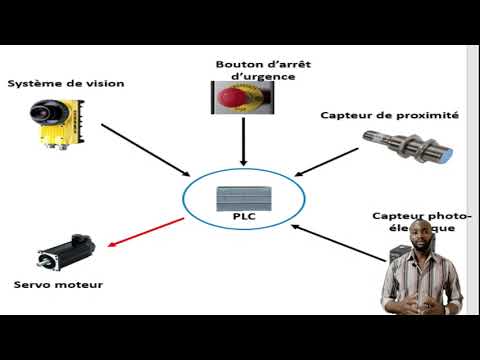

- Programmable Logic Controllers (PLC): Used to automate machines.

- Distributed Control Systems (DCS): For controlling complex processes.

- Robotics: Robots used for specific tasks such as welding, assembly, etc.

- Sensors and actuators: For data collection and physical control.

How does automation affect employment in the industry? Automation can lead to a reduction in certain types of jobs, but it also creates new roles in programming, maintenance, and management of automated systems. It is essential to train employees on new technologies.

Which sectors benefit the most from automation?

- Manufacturing: Improvement in production and assembly.

- Oil and gas: Monitoring and control of facilities.

- Food and beverage: Quality control and production processes.

- Pharmaceutical: Standardization of processes and traceability.

What challenges are associated with industrial automation?

- High initial costs: Investment needed to set up automated systems.

- Implementation complexity: Integrating new technologies into existing systems.

- Resistance to change: Employees may be reluctant to adopt new ways of working.

How can industrial automation contribute to sustainability? Automation can reduce energy consumption and minimize waste by optimizing processes. Additionally, it allows for better monitoring and control of resources.

What is the future of industrial automation? The future of industrial automation looks promising, with the integration of advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT), making systems smarter and more adaptable.