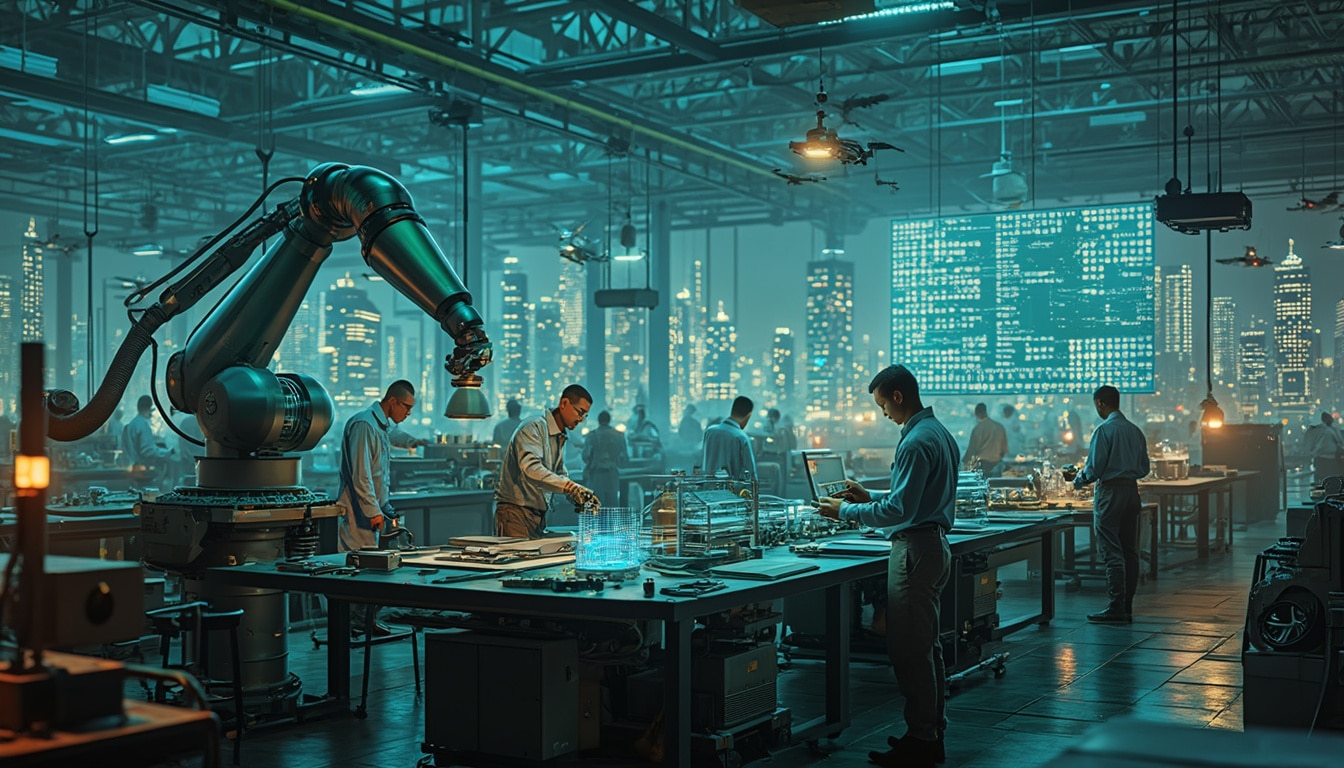

The evolution of the Industry 4.0 market is taking shape with impressive vigor. Anticipating a phenomenal increase of 14.80% per year until 2032, this digital revolution promises to profoundly transform our production methods. Emerging technologies, such as artificial intelligence, the Internet of Things, and digital twins, play a central role in this growth. This dynamism offers unique opportunities for companies looking to modernize their supply chains, improve their energy efficiency, and optimize their productivity. 💡

Industry 4.0 is propelled to new heights, with impressive annual growth forecasts. According to the latest analyses by MRFR, this sector is expected to experience significant expansion with a compound annual growth rate (CAGR) of 14.80% by 2032. This advancement is primarily driven by technological innovation and the integration of cutting-edge digital solutions, notably artificial intelligence and the Internet of Things. In light of these disruptions, companies are increasingly encouraged to adopt these new technologies to optimize their processes and enhance their competitiveness in the global market.

Table des matières

ToggleRapid evolution and challenges of Industry 4.0

With a projected annual growth of 14.80% by 2032, Industry 4.0 represents a profound transformation of the global industrial landscape. This development is fueled by technological innovations and the growing integration of artificial intelligence. Companies, whether large or small, are seeking to adapt to this digital revolution to enhance their productivity. Cutting-edge technologies such as the Internet of Things (IoT), automation, and advanced data analytics play a key role in this dynamic. This enthusiasm is supported by the constant need to optimize production processes and create new business models focused on the total digitization of operations.

However, the implementation of Industry 4.0 is not without challenges. According to some studies, many obstacles relate to cybersecurity, the adoption of digital skills, and organizational change management. Despite these challenges, 17% of companies have demonstrated their ability to deploy solutions related to Industry 4.0 at the initially planned pace, reflecting a marked increase since 2023.

Market protagonists and technological implications

Key players in this transformation include renowned companies such as ABB Ltd., Siemens AG, and Schneider Electric. These companies are making significant investments in technologies that support digital transformation and improve energy efficiency. A concrete example is the effort invested in robotics solutions, which have become essential for optimizing production chains. These investments strengthen these companies’ positions in the market while promoting greater adoption of Industry 4.0 technologies.

Future perspectives and opportunities

As Industry 4.0 evolves, market opportunities are increasingly notable. Forecasts indicate that the global market could reach approximately 579.44 billion dollars by 2030. This growth potential proves particularly beneficial for traditional sectors eager to enhance their competitiveness and resilience. Initiatives such as the launch of the first 5G studio dedicated to Industry 4.0 in Singapore, in collaboration with giants like IBM and Samsung Electronics, reflect this momentum towards broader technological integration. This rapid progress illustrates how Industry 4.0 can redefine industrial standards and create even more interconnected ecosystems.