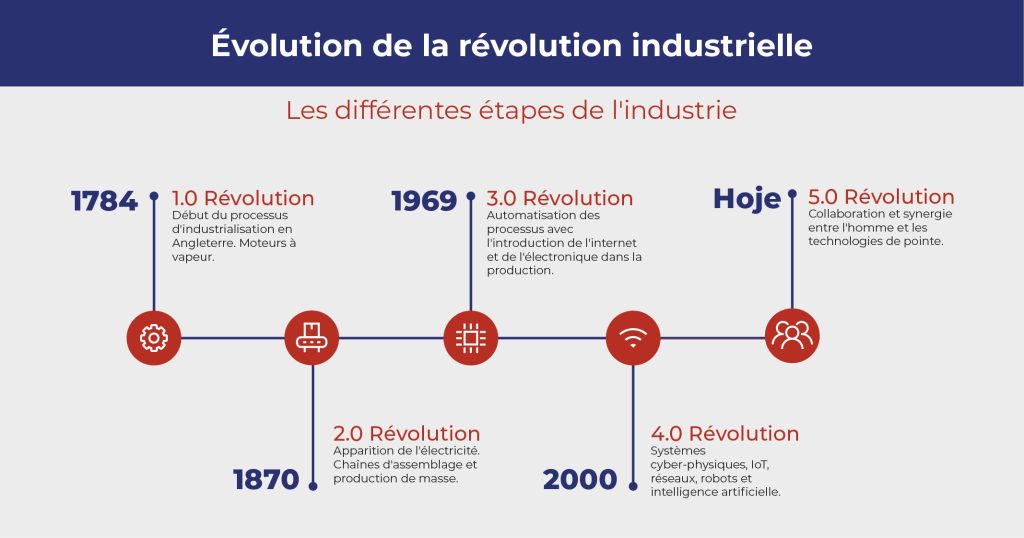

In a world of constant technological evolution, Industry 5.0 emerges as an innovative response to the increasing complexity of manufacturing processes. At the interface between man and machine, this new model highlights the human factor as a fundamental pillar of industrial transformation. Indeed, this approach aims to blend the innate skills of workers with the power of advanced technologies, such as artificial intelligence and cobots, to redefine the contours of production.

Far from relegating operators to the role of mere executors, Industry 5.0 places collaboration and creation at the heart of manufacturing activities. This translates into greater customization of products, an improvement in workplace safety, and a flourishing of human skills. In this context, workers become true actors of innovation, acting in synergy with technologies to meet contemporary challenges. The study of the benefits of Industry 5.0 in the manufacturing sector invites us to rethink our relationship with work and to envision a future where humans and machines coexist in a harmonious and productive manner.

With the emergence of Industry 5.0, a crucial question arises: how can humans become the central pillar in an increasingly digitized and automated world? Industry 5.0 envisions a harmonious collaboration between advanced machines, such as robots and Artificial Intelligence (AI), and human workers, thus redefining the role of humans in the manufacturing sector. This transformation is not simply a technological add-on, but a true humanist revolution that brings tangible benefits to companies and their employees.

Table des matières

ToggleIncreased Productivity through the Integration of Human Skills

One of the main advantages of Industry 5.0 is the significant increase in productivity. According to a study conducted by the European Commission, companies that adopt this new approach see an average productivity increase of 20%. Why such an improvement? The answer lies in the optimization of the use of human skills.

In the manufacturing sector, the role of workers is evolving from passive operators to active participants in the production process. For example, in an automotive parts manufacturing plant, cobots (collaborative robots) are deployed to assist workers with repetitive tasks and heavy lifting. This enables employees to focus on tasks that require analytical and creative skills, such as problem-solving and innovation.

A tangible example is provided by a leading company in high-performance composites. By integrating cobots into their production line, this company not only reduced the number of workplace accidents but also allowed its employees to acquire new skills using advanced technologies. They transitioned from mere operators to experts capable of virtually overseeing and optimizing the manufacturing process.

Workplace Safety and Employee Well-being: A Priority

In a world where workplace safety is a major issue, Industry 5.0 stands out as a pioneering model. By integrating advanced technologies into the production process, companies achieve notable advances in health and safety. The implementation of technological solutions to monitor and analyze working conditions in real-time helps to reduce accident risks.

For example, data analysis systems track employee movements using sensors, identifying risky behaviors and enabling proactive interventions. A recent study shows that companies adopting such technologies have reduced their workplace accidents by 30% in less than two years.

Moreover, the human approach of Industry 5.0 promotes a better work-life balance. By offering employees greater autonomy and flexibility in managing their schedules and working conditions, these companies are aligned with the overall well-being of employees. This contributes to talent retention and a reduction in turnover, a major issue for today’s companies.

Renewed Skills: Investing in the Future

Another essential asset of Industry 5.0 lies in the emphasis on skill development. As advanced technologies take a prominent place in the manufacturing sector, it is imperative that workers receive adequate training to adapt to these changes. Industry 5.0 aims to redefine the necessary skills, placing humans at the center of digital transformation.

Some companies have already started adopting training programs specifically designed to meet the requirements of Industry 5.0. For example, a continuing education program has been established within a large electronics company, offering employees courses on topics such as robotics, AI, and data analysis. Not only does this allow them to feel valued, but it also increases the capacity for innovation within the company.

A report from the International Labour Organization (ILO) indicates that companies investing in the continuing education of employees see a 30% increase in the innovation produced within their teams. Thus, investing in human skills emerges as an essential vector of competitiveness in the new manufacturing landscape.

All of this creates a dynamic where workers are not just resources, but catalysts for change, capable of transforming challenges into opportunities. With adequate training, they can bring new ideas and tailored solutions to contemporary issues, making the manufacturing sector both more resilient and agile.

An Ethical and Responsible Dimension: Redefining the Role of Industry

Finally, Industry 5.0 also addresses the ethical and responsible dimension of manufacturing operations. With the growing awareness of environmental issues, companies must not only focus on productivity but also on their impact on society. Technological innovation, when used responsibly, can significantly reduce the ecological footprint of industries.

Initiatives such as the use of sustainable materials and recycling industrial waste are becoming priorities for companies engaged in this transition to Industry 5.0. Furthermore, workers are often at the forefront of these changes. By collaborating with research and development teams, they can propose solutions for waste reduction or improvements in manufacturing processes to make them less resource-intensive.

A notable example is that of a consumer goods company that involved its employees in a sustainable development project aimed at reducing plastic in its production lines. Through worker feedback, the company succeeded in reducing its plastic consumption by 40% while maintaining its production processes at a high level of efficiency.

By fostering this dialogue between technology and human beings, Industry 5.0 positions itself as both a productive and responsible actor, aware of its role in the transition towards a sustainable and ethical future. This model helps to build trust between employees and the company, thereby establishing solid foundations for long-term cooperation.

Ultimately, Industry 5.0 is a vector of transformation that emphasizes the human element in all its dimensions: productivity, safety, skill development, and responsibility. By reinventing the role of humans in the manufacturing sector, this new era offers innovative and promising perspectives for creating a more fulfilling and sustainable work environment.

FAQ on the Human Advantage of Industry 5.0 in the Manufacturing Sector

What is Industry 5.0? Industry 5.0 refers to a new era in the industrial revolution that places humans at the center of production processes, promoting collaboration between workers and advanced technologies.

How does Industry 5.0 improve workplace safety? By integrating technologies such as cobots (collaborative robots), Industry 5.0 enhances safety by reducing dangerous tasks and allowing workers to focus on high-value missions.

What are the advantages of humans in Industry 5.0? Humans bring flexibility, creativity, and problem-solving abilities that cannot be matched by machines. This helps improve productivity and innovation.

How does Industry 5.0 influence worker training? The transition to Industry 5.0 requires continuous training focused on developing digital and technical skills to enable better interaction with advanced technologies.

What technologies are involved in Industry 5.0? Industry 5.0 utilizes technologies like the Internet of Things, artificial intelligence, and augmented reality, which support humans in their tasks while enhancing process efficiency.

How does Industry 5.0 promote work-life balance? By optimizing production processes with technology, Industry 5.0 allows workers to have more flexible schedules and better time management.

“`