Table des matières

ToggleTechnologies Used in Industry 4.0

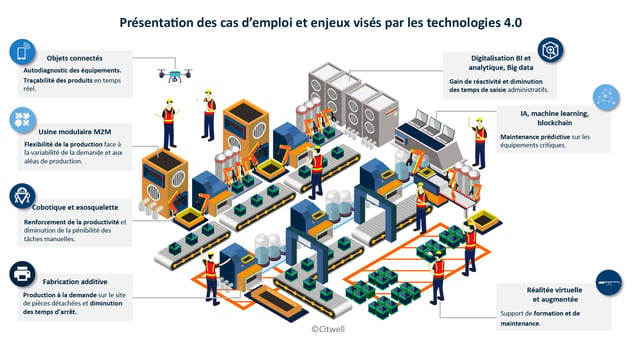

Industry 4.0 is radically transforming production processes, and its implications go far beyond mere productivity gains. It also has a significant impact on worker health through the integration of new technologies.

Advancements in smart sensors allow for real-time monitoring of the work environment. These sensors detect anomalies such as high noise levels, excessive vibrations, or temperature variations, which helps to anticipate and correct health risks.

Collaborative robots, or cobots, have become indispensable. They take on repetitive and dangerous tasks, thereby reducing the risk of injuries and musculoskeletal disorders among employees. Their intuitive and safe interaction with humans not only enhances efficiency but also improves workplace well-being.

The use of augmented reality (AR) and virtual reality (VR) offers immersive training solutions, preparing employees for complex tasks without exposing them to real dangers. These technologies also enable the simulation of emergency scenarios, thus improving team preparedness and responsiveness.

Data management systems based on artificial intelligence (AI) help analyze and optimize working conditions. By leveraging large amounts of collected data, these systems identify trends and potential hazardous issues, allowing companies to take proactive measures.

Finally, wearable devices, such as smartwatches and smart clothing, continuously monitor employees’ vital signs. These devices alert in case of health issues, such as high levels of stress or fatigue, promoting quick and effective interventions.

By integrating these technologies, Industry 4.0 not only optimizes production but also plays a crucial role in preserving and improving worker health, thereby revolutionizing the approach to safety and well-being at work.

Artificial Intelligence

Industry 4.0 is profoundly transforming our way of working by integrating cutting-edge technologies. One of the most striking aspects of this transformation is its impact on health. New technologies offer innovative solutions to improve working conditions, reduce occupational risks, and even promote employee well-being.

Among the technologies used in the context of Industry 4.0, some play a key role in this evolution. These include:

- Collaborative robots, which work alongside humans to reduce repetitive and strenuous tasks.

- IoT sensors (Internet of Things) that monitor working conditions in real-time and ensure operator safety.

- Augmented reality to train employees in an immersive and safe manner.

- 3D printing for manufacturing ergonomic and customized equipment.

In terms of artificial intelligence (AI), its role is also crucial. AI allows for the analysis of large amounts of data to identify potential risks and optimize production processes. It contributes to the prevention of incidents by detecting anomalies before they cause problems. Moreover, machine learning algorithms can adapt work environments based on the specific needs of each employee, thus providing a safer and healthier work experience.

Internet of Things

Industry 4.0 is disrupting traditional production methods through the integration of advanced technologies, which has direct repercussions on the health of workers. Some of the most significant technologies include collaborative robots, the Internet of Things (IoT), and artificial intelligence (AI).

Collaborative robots help automate repetitive and dangerous tasks, thereby reducing injury risks. AI and machine learning allow for real-time data analysis and predicting failures before they cause accidents. Additionally, augmented reality (AR) systems provide immersive training that improves employee preparedness for dangerous situations.

The Internet of Things (IoT) plays a crucial role in this revolution. It consists of connected sensors that collect data to optimize decisions and ensure safety in the workplace. For example, sensors can monitor toxic gas levels and trigger alerts in case of danger.

- Connected devices monitor employee health in real-time, tracking variables like heart rate and stress levels.

- Smart clothing equipped with sensors detects incorrect postures and encourages proper ergonomics.

- Wearable devices provide immediate alerts in case of incidents, ensuring quick intervention.

The integration of IoT in Industry 4.0 thus facilitates proactive management of workplace health by anticipating problems before they become critical.