The transition to Industry 4.0 represents a crucial challenge for many French industrial companies, which are still struggling to fully embrace digital transformation. While the technological revolution offers immense potential for connected, robotic, and intelligent factories, only 10% of these factories have been fully digitized. This paradox illustrates the persistent disconnects between technological opportunities and their effective implementation, requiring a fundamental cultural and educational adaptation within companies to truly thrive in this new industrial era.

The revolution of Industry 4.0, while promising, is often slowed down by organizational, technological, and cultural disconnects within French industrial companies. This article examines the causes of this paradox, presents the main challenges, and offers concrete solutions to overcome these obstacles and succeed in digital transformation.

Table des matières

ToggleThe Paradox of Industry 4.0

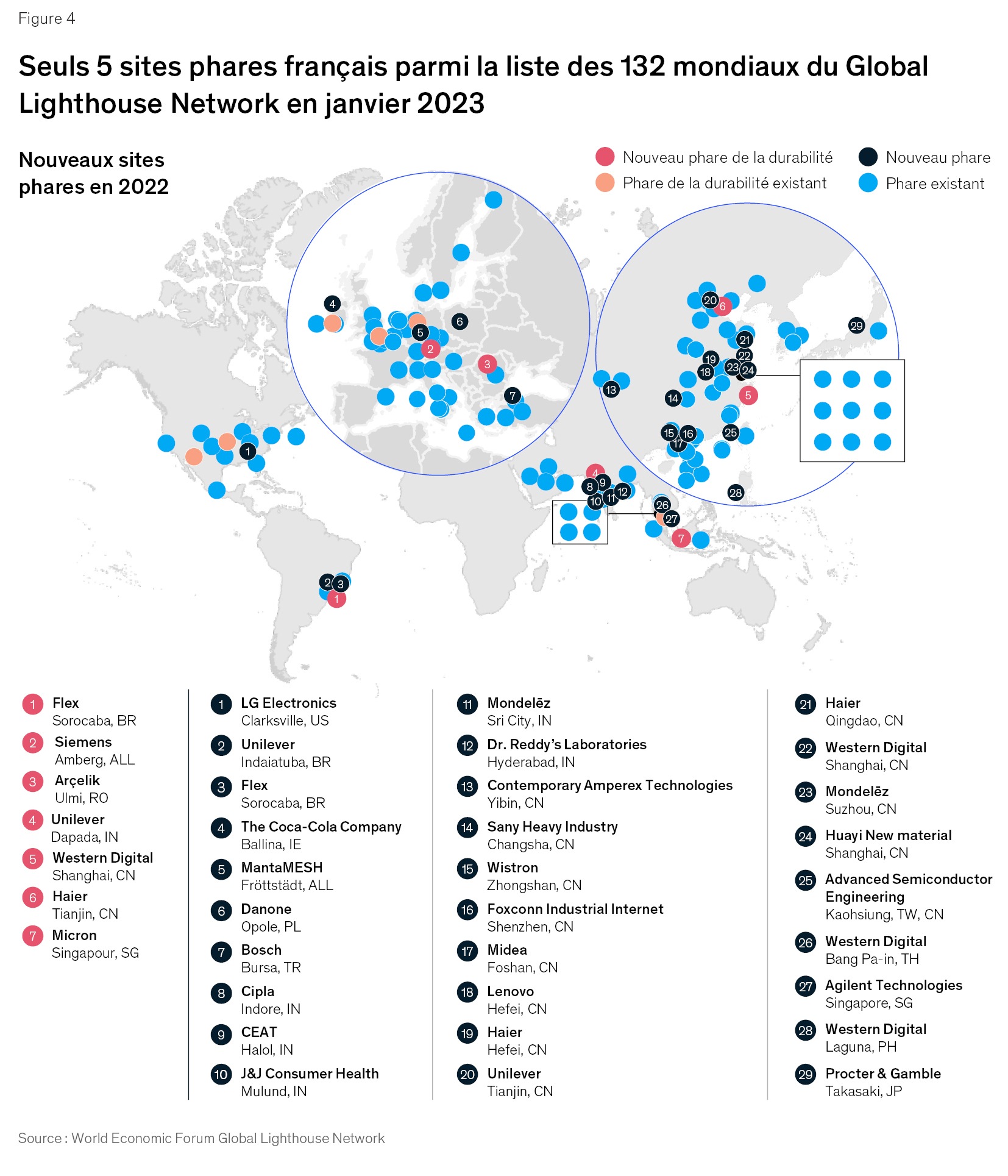

Industry 4.0, also known as the factory of the future, is a technological revolution aimed at transforming traditional production methods through the integration of advanced technologies such as the Internet of Things (IoT), robotics, and artificial intelligence. Yet, despite its promises of increased productivity and efficiency, only 10% of French factories are currently fully digitized.

Understanding Technological Disconnects

One of the main causes of the delay is linked to technological disconnects. In France, many industrial companies lack the necessary infrastructure to integrate these new technologies. Outdated production systems, inadequate IT networks, and a shortage of technical skills significantly hinder progress toward a true connected factory.

Organizational and Cultural Challenges

In addition to technological challenges, companies must also face organizational and cultural disconnects. Digital transformation requires a profound adaptation of internal processes and structures. This encompasses employee training, the reconfiguration of production lines, and the adoption of a new culture of innovation. Unfortunately, many companies struggle to find a balance between technological transformation and organizational adaptation.

Employee Training and Awareness

To overcome cultural resistance, it is imperative to train and raise awareness among employees about the benefits of Industry 4.0. Training workshops, seminars, and educational programs help illuminate employees about new practices and technologies, thus reducing apprehensions and fostering engagement.

Rethinking Internal Processes and Structures

The digitization of factories cannot occur with outdated methods. It is crucial to rethink internal processes to align them with the demands of modern technologies. This includes redesigning production lines, optimizing workflows, and improving communication between various production units.

Solutions for Successful Transformation

To achieve digital transformation, it is important to adopt a holistic approach that encompasses technological, organizational, and cultural aspects. Investments in infrastructure, ongoing training programs, and clear communication about goals and expectations are essential to ensure a smooth transition to Industry 4.0.

Investing in Appropriate Technologies

Companies need to invest in appropriate technologies such as advanced IoT systems, intelligent robots, and optimized production management software. These investments may seem costly in the short term, but they will lead to significant gains in productivity and competitiveness in the long term.

Promoting Continuous Innovation

Encouraging a culture of continuous innovation is essential to maintain the momentum of digital transformation. Companies should create environments conducive to experimentation and the adoption of new ideas, while remaining agile to adapt to technological changes.

In conclusion, the paradox of Industry 4.0 in France lies in the gap between technological ambitions and organizational realities. Overcoming these disconnects requires an integrated strategy and a strong commitment to transformation at all levels of the company. Only a sincere commitment to bridging these gaps will allow French companies to fully benefit from the advantages of Industry 4.0.

Challenges

- Slow adoption of technologies.

- Lack of digital skills among employees.

- High initial investments required.

- Reluctance to organizational change.

- Technological fragmentation within existing systems.

Solutions

- Ongoing training of workers.

- Progressive integration of new technologies.

- Financial subsidies and aids for innovation.

- Improvement of company culture towards digital.

- Harmonization of technological systems.

https://twitter.com/FR_Industrie/status/1793210915799568520