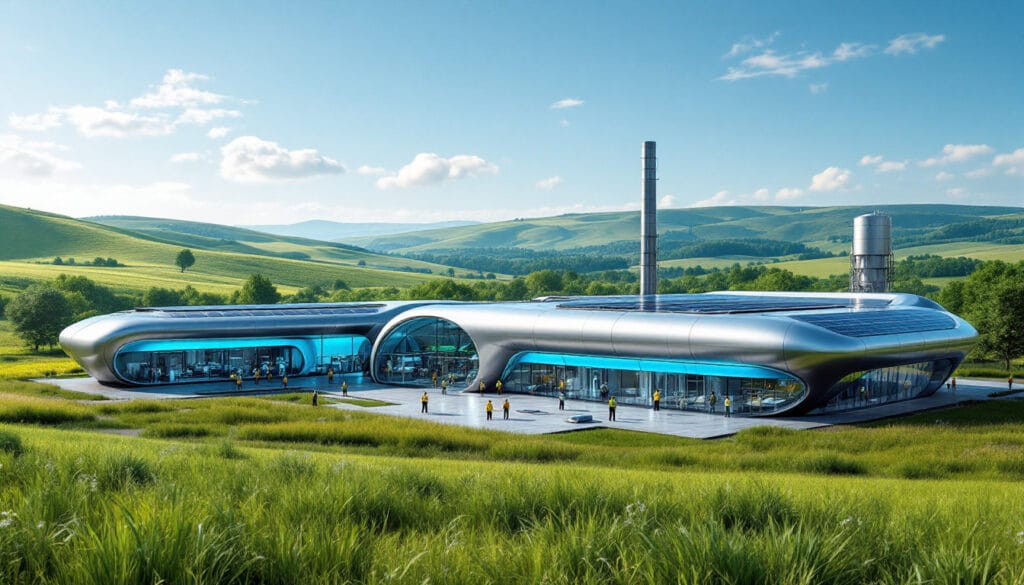

As part of the technological advancements in the aluminium industry, EGA’s EX technology pilot project stands out for its ability to transform the sector. By exploring new avenues for more efficient and environmentally friendly production, this project paves the way for the implementation of crucial innovations. By achieving optimized industrial performance, it symbolizes a decisive step towards an era where aluminium is combined with sustainability and innovation. This project testifies to the commitment to aluminium production that combines technological advancements with responsible practices.

The pilot project of Emirates Global Aluminium’s EX technology significantly illustrates advancements in the aluminium industry. This initiative aims to demonstrate the integration of innovative methods to improve efficiency and reduce the carbon footprint in aluminium production. Through strategic investments, EGA positions itself at the forefront of efforts to achieve sustainable production. The use of cutting-edge technologies not only optimizes industrial processes but also contributes to a transition towards a more eco-friendly and resilient economic model.

Table des matières

Togglethe pilot project of EGA’s EX technology: a revolution in aluminium

The pilot project of EX technology developed by Emirates Global Aluminium (EGA) aims to redefine the future of the aluminium industry. This project promotes significant advancements that optimize not only production processes but also enhance environmental sustainability. Through cutting-edge technological innovations, EGA strives to reduce the carbon footprint associated with aluminium production. By adopting EX technology, the company envisions a more efficient and eco-friendly production.

impacts of EX technology on the aluminium industry

The implementation of EX technology significantly impacts the aluminium sector. This pilot project promotes the integration of advanced techniques, allowing for increased productivity while minimizing the necessary resources. The new equipment, specifically designed for this purpose, enables better energy management and optimizes production costs. EGA thus demonstrates that the industry can evolve toward more sustainable practices without compromising efficiency and product quality.

the challenges to overcome for successful implementation

For the EX technology to reach its full potential, several challenges must be addressed. Managing initial costs and training personnel are among the priorities. Additionally, convincing stakeholders of the economic and environmental viability of this technological revolution is essential. EGA must also ensure that the adoption of these new technologies does not disrupt the current production chain but optimizes it harmoniously to ensure a successful transition.