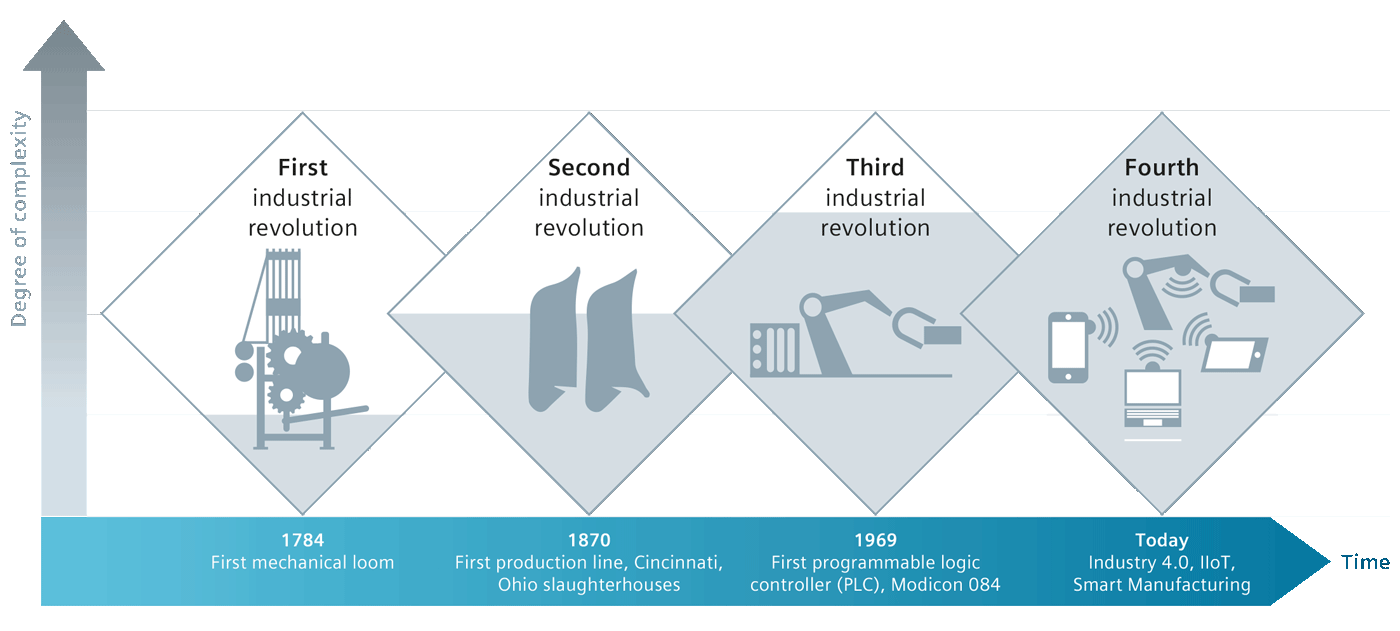

Driven by the rise of innovative technologies, Industry 4.0 is redefining the manufacturing horizon with significant advancements in Indiana. Between enhanced automation and connected factories, experts and industrialists are embarking on a bold digital transformation. This fourth industrial revolution marks a turning point where production becomes intelligent, merging the Internet of Things, machine learning, and collaborative platforms to reshape the industrial landscape.

In Indiana, a new momentum towards the Fourth Industrial Revolution is noticeable as experts and industrialists actively engage in the digital transformation of factories. Supported by innovations from industrial Internet of Things and artificial intelligence, these efforts are redefining what it means to be a connected factory. Modern technologies enable automated and intelligent production, symbols of this burgeoning fourth industrial revolution.

Table des matières

Togglethe emergence of industry 4.0 in Indiana

Indiana is at the heart of a remarkable transformation with the advent of industry 4.0, a technological evolution that fundamentally changes how factories operate. This industrial revolution invites experts and industrialists in the region to integrate technologies such as the Internet of Things (IoT) and artificial intelligence into their daily operations. This creates a more agile and connected production ecosystem, a significant and necessary leap forward to remain competitive in the global market.

Regional initiatives to embrace smart industry are multiplying, with intensive training programs aimed at preparing the workforce for the contemporary challenges of this new digital era. Experts encourage industrialists to revise their traditional infrastructures to promote a profound digital transformation. Indiana is thus positioning its factories as pioneers in adopting automated and interconnected systems.

technologies serving innovation

Industry 4.0 in Indiana relies on spectacular advancements, particularly in the fields of automation and . These technologies allow for increased product customization and a significant reduction in time to market. Local factories, by optimizing their production processes, are seeing their efficiency reach new heights, powered by software capable of managing data in real-time. The potential for improving product quality and customer satisfaction continues to grow, offering businesses the opportunity to stand out in a highly competitive environment.

the impact on the industrial ecosystem

As industry 4.0 continues to evolve, its impact is also felt throughout the entire industrial ecosystem of Indiana. Small and medium-sized enterprises benefit from collaborative solutions that allow them to integrate these technologies without incurring prohibitive costs. This synergy strengthens the local industrial fabric, integrating more resilient and agile value chains. Local industrialists, using these new tools, are developing more robust business strategies that are open to continuous innovation, thereby ensuring the economic future of the region.

✍️ Dans une tribune parue dans @lopinion_fr, @tprebay Directeur général adjoint, livre son éclairage sur le lien entre robotisation nippone et la révolution industrielle 4.0 dans la recherche de la productivité.

— Financière ARBEVEL (@Fin_Arbevel) May 10, 2021

➡️ https://t.co/zk9L8Ru5g0#AssetManagement #innovation pic.twitter.com/hdoNK2OdCy