At the heart of the modern industrial revolution, artificial intelligence acts as the conductor, orchestrating the profound transformation of the manufacturing industry. Going well beyond mere optimization of production, AI is redefining manufacturing standards by initiating a shift towards Industry 4.0, where automation and system integration become the new norms. Thanks to neural networks, machine learning, and predictive maintenance, this technology allows not only for cost reduction but also provides increased efficiency by optimizing every step of the production process. AI is not just a tool; it is the engine of a true industrial metamorphosis.

In the fascinating world of Industry 4.0, the use of artificial intelligence (AI) is redefining the manufacturing industry. AI offers unprecedented optimization of production by integrating advanced automation systems. Technologies such as machine learning and neural networks are transforming the way we produce, store, and perform predictive maintenance of systems. The industry, once dependent on manual processes, is metamorphosing into an intelligent ecosystem where digitalization and data analysis are the main engines. This digital revolution propels us towards a future where smart factories are not only more efficient but also capable of adapting to changes through the wise use of connected technologies. The road to industrial efficiency has undergone a radical transformation.

The manufacturing industry is entering a new era with the advent of artificial intelligence (AI), which promises to revolutionize existing processes. Machine learning algorithms and neural networks enable the optimization of each step of the production chain. By analyzing huge volumes of data, AI identifies inefficiencies and proposes solutions to improve yield. Such a level of precision was unattainable with traditional methods, providing companies with increased competitiveness. By integrating these technologies, factories can now predict failures before they occur, thus reducing downtime and increasing operational safety.

Table des matières

ToggleOptimization of Production through Artificial Intelligence

Improving manufacturing production has always been a challenge, but thanks to AI, this task is becoming increasingly accessible. Manufacturers can now use predictive models to anticipate resource needs and adjust production schedules in real time, thus avoiding surpluses and shortages. Optimization also includes the analysis of data in real time, allowing rapid adaptation of the production chain according to fluctuating demands. Solutions such as vision systems equipped with intelligent cameras inspect products to detect defects as soon as they appear, thus ensuring consistent quality. This reduces costs associated with production rework and increases customer satisfaction.

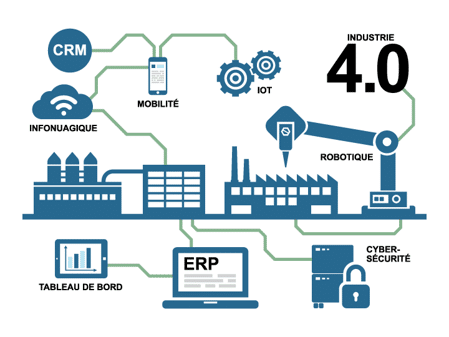

Metamorphosis towards Industry 4.0

The interface between AI and Industry 4.0 opens new perspectives for companies eager to transform. This new industrial revolution promotes the integration of cyber-physical systems and the interoperability of digital technologies. Initiatives such as the development of private 5G networks and the use of digital twins enable manufacturers to be at the forefront of innovation. Digital transformation capitalizes on AI capabilities to create smart factories where machines, systems, and humans collaborate effectively. This requires an intensive reskilling of teams to navigate this new complex ecosystem, highlighting the importance of new skills and empowering tomorrow’s workforce.