Industrial Ethernet is progressively establishing itself as a central pillar of modern production environments. By capitalizing on standardized Ethernet protocols, it optimizes communication in often complex and demanding industrial environments. Thanks to its ability to integrate robust network devices such as switches, it effectively competes with traditional Fieldbus protocols. These solutions, whether using copper wiring or fiber optics, ensure fast and reliable data transmission. The integration of Ethernet/IP and Ethercat principles also helps ensure real-time operation, thereby enhancing operational efficiency and predictive maintenance.

Industrial Ethernet refers to the use of standard Ethernet protocols in industrial environments. Compared to traditional Ethernet networks, Industrial Ethernet is designed to withstand harsh conditions such as extreme temperatures, vibrations, and electromagnetic interference. These networks used in the industry are often based on twisted pair copper wiring or fiber optics.

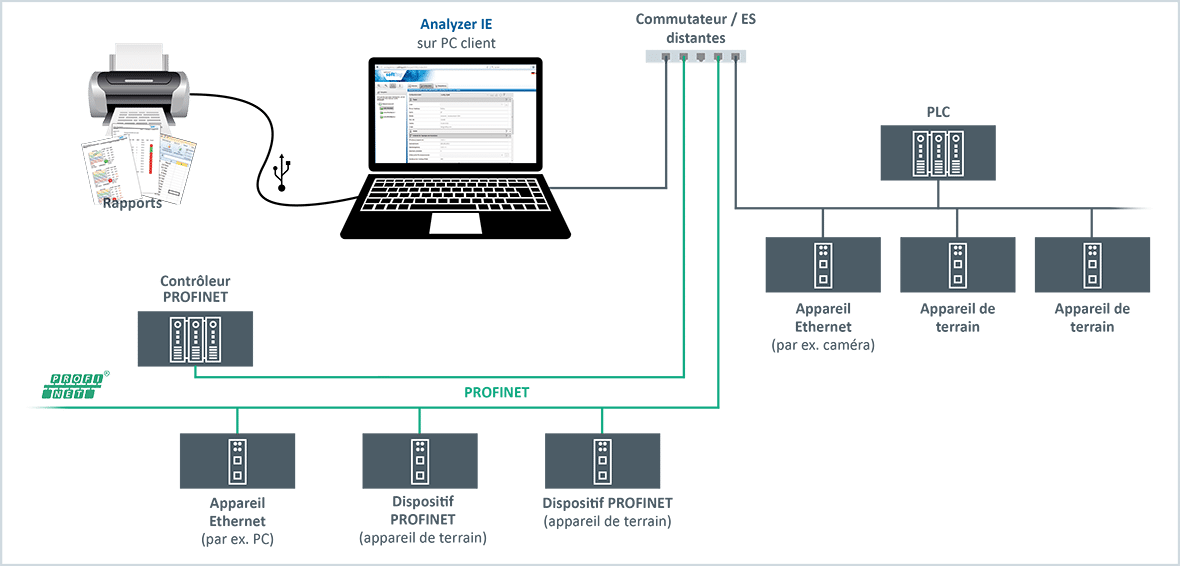

Communication Protocols: One of the key elements of Industrial Ethernet lies in its ability to utilize a variety of protocols such as Profinet and Ethernet/IP. Profinet is an extension of TCP/IP, allowing communication from the field level to higher levels. On the other hand, Ethernet/IP is based on the CIP (Common Industrial Protocol) for interoperability between various devices.

OSI Model: To understand how Industrial Ethernet works, it’s essential to know the OSI model (Open Systems Interconnection). This model divides network services into seven distinct layers, ranging from the physical layer (layer 1) to the application layer (layer 7). Industrial Ethernet primarily uses the first layers to ensure fast and reliable communications.

Network Topologies: Industrial Ethernet networks can be configured in various topologies such as line, star, ring, or a combination of these. These configurations allow the network to be adapted to specific needs in terms of data rates, distances, and redundancy.

Real-Time Solutions: Some industrial processes require real-time communications. Technical solutions like Ethercat and specific versions of Ethernet/IP have been developed to meet these requirements where reliability and speed of data transfers are paramount.

Connectivity: A standard element of Industrial Ethernet is the RJ45 connector, although other technologies like gigabit Ethernet and Power over Ethernet (PoE) are becoming increasingly used. These technologies offer advancements in terms of speed and flexibility of installations. The connectivity may also include shielding to protect against interference.

I/O Modules: I/O modules such as Turck’s TBEN-L EtherNet/IP series allow for connecting multiple master channels simultaneously without losing efficiency. These modules provide a transmission speed of 10/100 Mb/s ensuring fast and efficient interactions for various industrial processes.

Standards and Categories: Industrial Ethernet cables are categorized according to their transmission performance, ranging from category 3 to category 7. The choice between these categories depends on the distance and rates required for the specific industrial application.

Finally, Industrial Ethernet is not just about physical connectivity, but also about smart contracts and other emerging technologies to improve production processes and supply chains. To learn more about these innovations, check out the article explaining how Nordson EFD received the Edge 2024 award for its PICO® Nexμs™ system: Nordson EFD receives the prestigious Edge 2024 award for its PICO® Nexμs™ jet system.

Table des matières

ToggleFAQ on Industrial Ethernet

Q: What is Industrial Ethernet?

A: Industrial Ethernet refers to the use of industrial protocols utilizing the standard Ethernet physical layer and standard Ethernet protocols for communications in industrial environments.

Q: What types of wiring are used with Industrial Ethernet applications?

A: Industrial Ethernet applications are designed to work with twisted pair copper wiring or fiber optics.

Q: What are the advantages of real-time Ethernet solutions?

A: Real-time Ethernet solutions enable fast and reliable communication, which is essential for operations where synchronization is crucial.

Q: How does Ethernet topology work in an industrial environment?

A: The topology of Industrial Ethernet typically relies on switches to create reliable networks capable of operating in harsh conditions.

Q: What is the difference between standard Ethernet and industrial Ethernet?

A: While standard Ethernet is used for general communications, Industrial Ethernet is specifically designed to meet the robustness and stability requirements of industrial environments.

“`