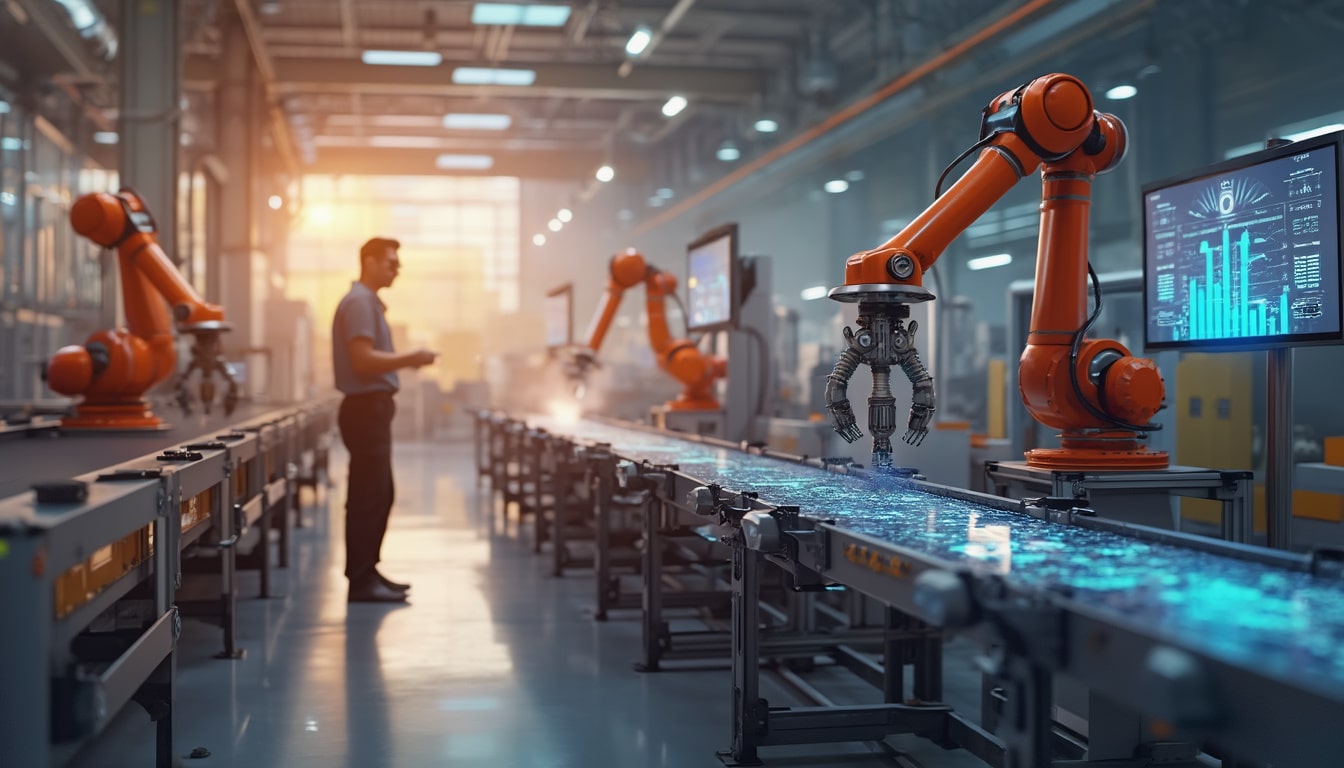

Industry 4.0 represents a major turning point for the manufacturing sector, integrating advanced technologies such as robotics and artificial intelligence at the heart of operations. This marriage of information technologies and traditional processes creates a hyper-connected ecosystem where data flows freely, promoting optimization and cost reduction. The introduction of the Internet of Things (IoT) and autonomous systems thus transforms factories into intelligent spaces capable of effectively responding to contemporary production challenges.

Industry 4.0, often called the fourth industrial revolution, represents the fusion of digital technologies with manufacturing operations. Relying on innovations such as advanced robotics, artificial intelligence, and the Internet of Things (IoT), it transforms factories into connected and intelligent environments. Thanks to these technologies, manufacturers can collect and analyze huge amounts of data to optimize processes, reduce costs, and improve product quality. Industry 4.0 also promotes decentralized and adaptable production, enabling a better response to consumer demand and enhancing industrial competitiveness.

Industry 4.0 symbolizes a radical transformation of the manufacturing sector, integrating cutting-edge technologies like advanced robotics and artificial intelligence to create smarter production environments. Thanks to automated systems, the supply chain becomes more fluid and responsive, thus reducing operational costs while improving product quality. This evolution is not just about integrating new machines but constitutes a complete redesign of industrial processes, introducing new modes of human-machine communication.

Table des matières

Togglethe technological components of industry 4.0

At the heart of Industry 4.0 are technologies such as the Internet of Things (IoT), which allows devices to collect and share critical data in real-time. Meanwhile, artificial intelligence and machine learning analyze this data, providing companies with valuable insights to anticipate failures or malfunctions. These technologies foster a production environment where machines can “communicate” with each other, thus optimizing the entire manufacturing process.

the benefits of industry 4.0 for manufacturing companies

The adoption of Industry 4.0 promises significant benefits for manufacturing companies. It fosters an increase in competitiveness by enabling production at lower costs without systematically resorting to offshoring. By optimizing processes through data analysis and automation, companies see their productivity and profitability increase. Moreover, the precise monitoring of operations improves traceability, simplifying administrative tasks and ensuring greater compliance with regulatory standards, while ensuring improved customer satisfaction.

[#SGSolution]

— Saint-Gobain (@saintgobain) August 5, 2024

🤖1 minute pour comprendre l'industrie 4.0 : Plongez au cœur de cette quatrième révolution industrielle et découvrez ses secrets les mieux gardés.

✒️@Batinfo_com

🔗https://t.co/1PuAxfjsU1 pic.twitter.com/SzYitXAOEm