In a world of constant technological evolution, the advent of Industry 5.0 is heralding a true revolution in the way factories are designed and managed. More human-centered than ever, this new era promises to profoundly transform our relationship with industrial production. Discover how Industry 5.0 is shaping a future where cutting-edge technologies and worker well-being combine to create an innovative and efficient work environment.

Table des matières

ToggleIndustry 5.0: The Human-Centered Future

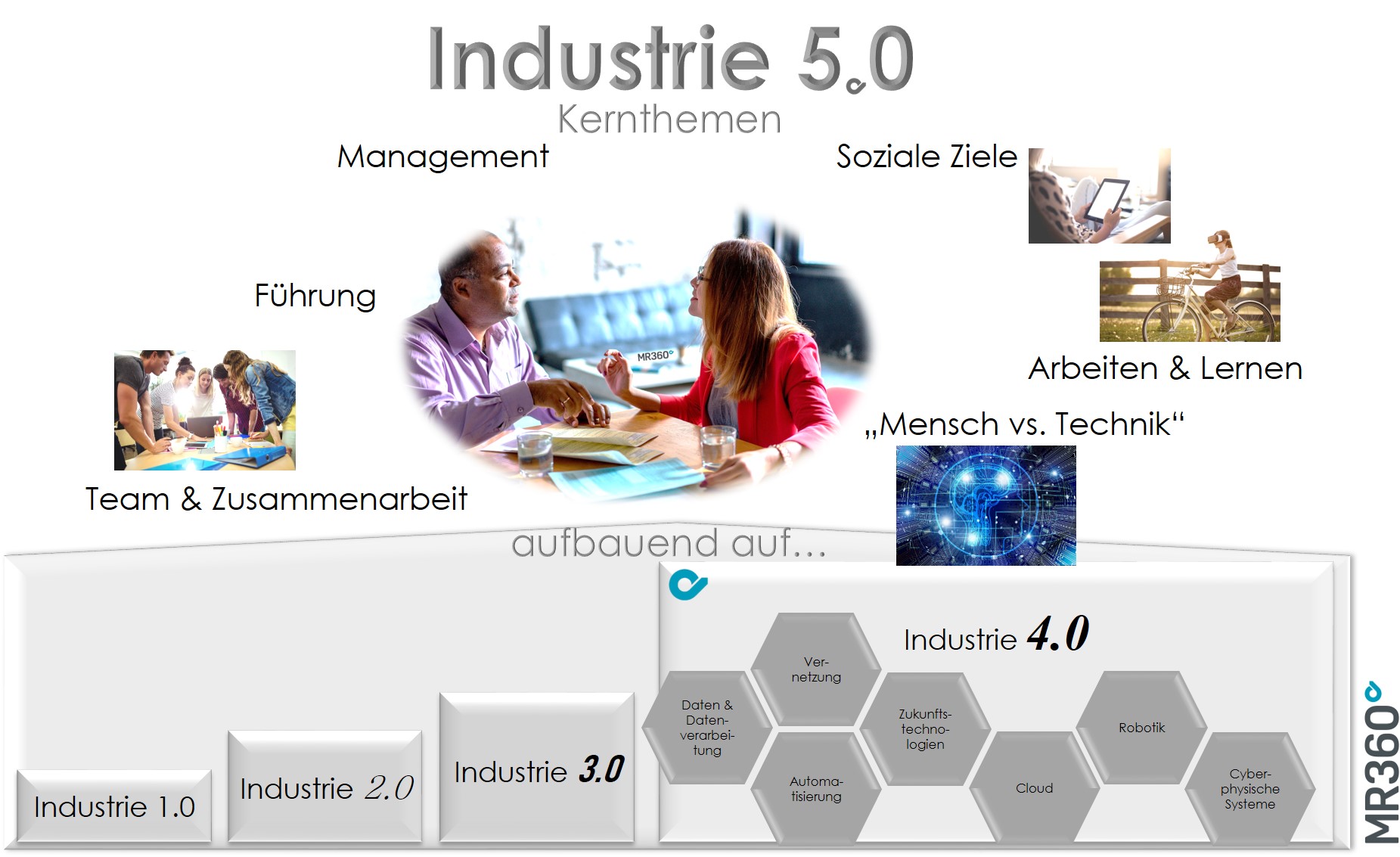

The transition from Industry 4.0 to Industry 5.0 marks a significant turning point for the manufacturing sector. While Industry 4.0 focused on automation and advanced technologies, Industry 5.0 places humans at the heart of production processes. This evolution promises a radical change in how we design and operate factories.

Fundamental Principles of Industry 5.0

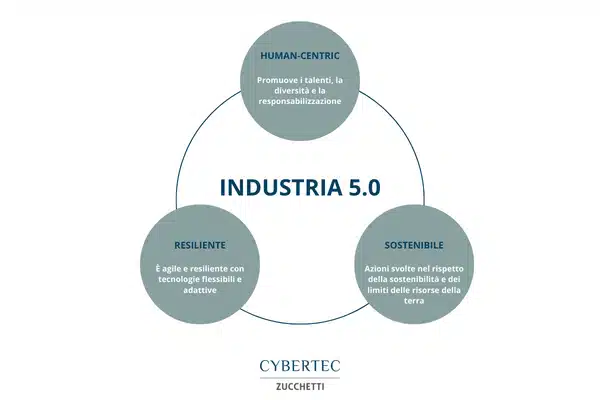

Unlike its predecessors, Industry 5.0 stands out with its humanistic approach. It integrates advanced technologies while ensuring employee well-being. These principles include:

- Human Centricity: Prioritizing worker well-being.

- Sustainability: Ecologically responsible operations.

- Mass Customization: Adapting products to individual needs.

Technological Evolution and Employee Well-Being

The factories of the future will be characterized by close collaboration between humans and machines. Advances in artificial intelligence and machine learning will enable workers to perform more rewarding and less repetitive tasks.

Rapid Adoption and Competitive Advantages

According to the report from Info-Tech Research Group, the adoption of Industry 5.0 is faster than that of Industry 4.0 due to the widespread acceptance of technologies integrating AI and human capabilities. Companies that embrace this evolution will be able to benefit from:

- Efficiency Gains: Optimization of production processes.

- Quality Improvement: Innovative and high-quality products.

- Sustainable Growth: Maintaining competitive advantage and adapting to future challenges.

Strategic Transformation and Long-Term Impacts

The shift to Industry 5.0 is not just about integrating new technologies. It is a strategic transformation of manufacturing practices aimed at several objectives:

- Integration of Legacy Systems: Modernizing existing infrastructures.

- Skill Development: Ongoing training for employees.

- Data Management: Effective use of data for decision-making.

Collaborative and Eco-Friendly Factories

Industry 5.0 promotes factories that are not only collaborative but also environmentally friendly. By combining the best practices of Industry 4.0 and the principles of Industry 5.0, companies can meet current market demands while anticipating future challenges.

| Aspects of Industry 4.0 | Innovations of Industry 5.0 |

| Automation | Human-Machine Collaboration |

| Cutting-edge Technologies | Employee Well-Being |

| Mass Production | Mass Customization |

| Process Optimization | Sustainability and Resilience |

📢Learning EXpedition Grand Est

— Digiworld-Institute (@DigiworldInst) July 3, 2023

Industrie 5.0 : construire l’industrie européenne du futur grâce aux technologies numériques

📍Jeudi 6 juillet | 9h-17h à Strasbourg

Plus que quelques places disponibles !

Inscription : contact@digiworldinstitute.org

Au programme 👇 pic.twitter.com/I4Mep1FqfM