As part of the technological revolution driven by Industry 4.0, a question concerns many workers: will artificial intelligence really replace our jobs? The emergence of these innovative technologies raises both admiration and fear regarding their impact on the labor market. A reflection is necessary on the challenges and opportunities that this major transformation could bring for the world of work.

Table des matières

ToggleThe advantages of AI in Industry 4.0

Artificial intelligence (AI), machine learning, and robots bring significant improvements to industrial processes. By increasing efficiency, enhancing quality control, and reducing costs, AI helps companies optimize their manufacturing operations. Through real-time data analysis and quick decision-making, AI systems can predict maintenance needs and minimize downtime, thus significantly improving overall production.

Integration of AI and workforce development

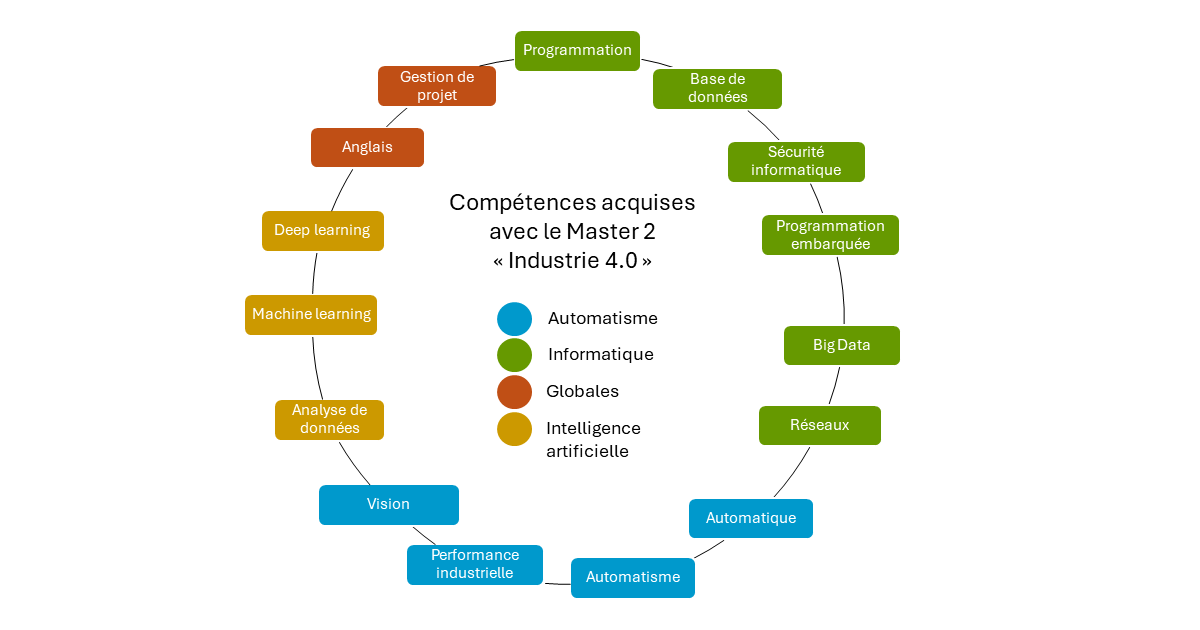

The adoption of AI requires more than technical adjustments. Industrial leaders must anticipate possible resistance from employees to the integration of AI. Good change management and adequate training are therefore essential. A gradual approach to AI ensures clear return on investment (ROI) over time. To succeed, it is crucial to balance external expertise, internal training, and workforce development.

Key drivers of Industry 4.0

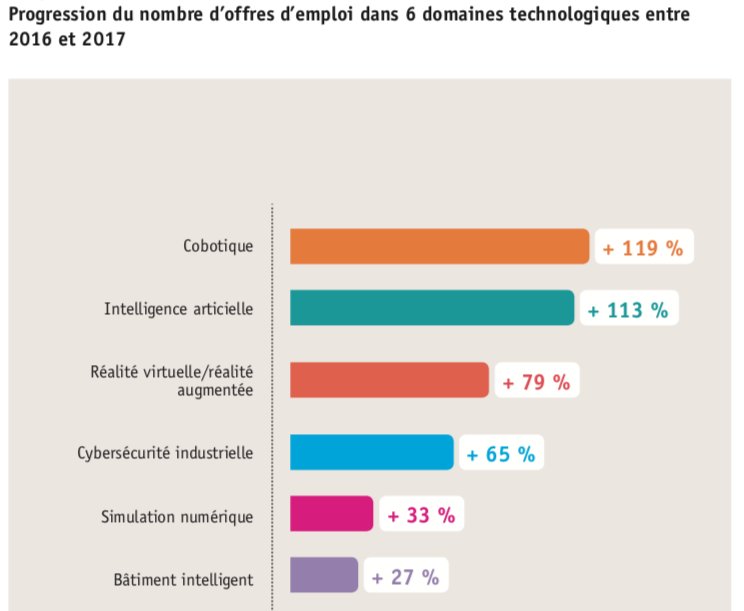

In India, the growth of machine learning and artificial intelligence integration in the manufacturing industry has reached 20% in the last two years, according to a PwC study. Industry 4.0 relies on the integration of digital technology, data analytics, and automation.

- IoT devices: Facilitate real-time data collection and exchange.

- Big Data and Analytics: Help identify relevant trends and patterns for data-driven decision-making.

- Automation: Improves accuracy and speeds up manufacturing processes with collaborative robots.

- Artificial intelligence: Allows machines to adapt to changing environments and optimize processes.

The benefits of AI for workforce management

Combining the rapid decision-making capabilities of AI systems with Industry 4.0 technologies revolutionizes operations and workforce management. Reducing human errors in labor-intensive industries, such as manufacturing, is crucial for operational efficiency. Automation through inventory management platforms using IoT sensors can accurately track products and update ordering systems.

Collaborative robots (cobots) work alongside humans to handle the most risky or complicated tasks, thus increasing workplace safety. AI is not aimed at replacing the most complex or creative aspects of human jobs but rather at automating repetitive and time-consuming tasks. This allows employees to focus on tasks they find more fulfilling.

An essential human-machine collaboration

Maintaining the balance between human needs and automation requirements in industrial and manufacturing sectors is a challenging but essential task. It is crucial to remember that automation does not replace human labor; it enhances employee potential with the precision and consistency of machines. By adopting this forward-thinking strategy, companies can navigate the complexities of the contemporary industrial world and position themselves for future success.

Comparison between the impact of AI and human skills

| AI | Human skills |

| Automation of repetitive tasks | Creativity and innovation |

| Real-time data analysis | Empathy and communication |

| Process optimization | Complex decision-making |

| Reduction of human errors | Adaptability and flexibility |

#Emploi | Le secteur de la sécurité privée poursuit ses recrutements pour les #Jeux🏅

— Préfecture de la région d’Île-de-France (@Prefet75_IDF) July 2, 2024

En collaboration avec @FranceTravail, 1 jobdating pour demandeurs d'emploi et étudiants s'est tenu à la préfecture ! 💼

Rencontre avec 3 candidats ⤵️

➕ d’infos👉https://t.co/aeaM5DehRy pic.twitter.com/V12T4jliVT